Decarbonization for a Net Zero Greenhouse Gas Future

Babcock & Wilcox has been on the clean energy "trend" for many decades and this is our history of carbon capture. We make big things happen through our B&W ClimateBright™ technological advancements that generate needed power, while lowering greenhouse gases and other emissions. And it all happens through B&W Research innovation.

B&W History of Carbon Capture

Our path to decarbonization

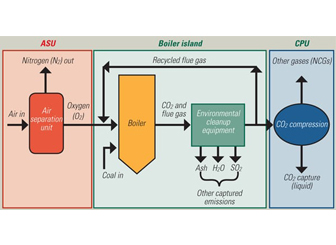

Babcock & Wilcox evaluated oxy-coal combustion for enhanced oil recovery at the request of a major oil company.

B&W joined the CANMET oxy-coal combustion consortium and participated in 1 MBtu/hr testing in Canada.

With support of the U.S. Department of Energy (DOE), B&W and Air Liquide (AL) began collaborating to bring advanced carbon capture and storage technology to the market for coal-fired electric power generation plants.

Oxy-coal combustion technology was successfully demonstrated at pilot scale in a B&W-owned small boiler simulator.

B&W began development of a post-combustion CO2 capture process.

B&W proposed retrofitting a 25 MWe boiler at the City of Hamilton, Ohio with oxy-combustion (to be sponsored by DOE and potentially the Ohio Coal Development Office).

Oxy-coal testing was conducted at B&W’s 30 MWt Clean Environment Development Facility in support of the SaskPower Shand project in Alberta, Canada, for enhanced oil recovery.

Conducted comprehensive CO2 solvent selection methodology in support of the commercial deployment of B&W’s RSAT CO2 post-combustion scrubbing process. Potential solvents were tested at three different facilities including a wetted-wall column, an RSAT bench-scale simulator, and an RSAT pilot plant.

Particularly in the U.S., interest in and demand for proven coal-fired power generation carbon capture and sequestration technologies was quickly growing. As such, B&W continued research and development activities working alongside the industry's most brilliant scientists and researchers. The company's state-of-the-art R&D center in Barberton, Ohio garnered national attention for the novel work of its researchers and our company.

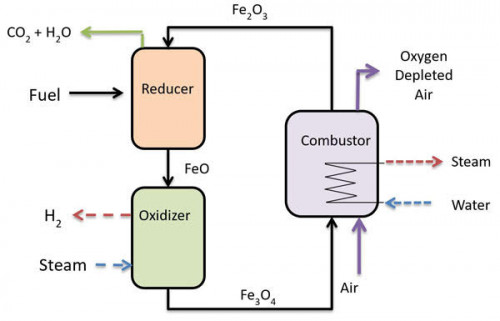

In conjunction with The Ohio State University (OSU), Babcock & Wilcox began development of advanced, next generation Coal Direct Chemical Looping technology which entails iron-based metal oxide particles circulating in a moving bed reducer coupled with an entrained-flow combustor.

B&W designed a 75 MW RSAT reference plant. The plant was engineered for 90% CO2 capture from a flue gas stream containing 1,500 metric tons of CO2 per day.

Oxy-coal combustion technology continued to show strong promise; engineering designs were developed for commercial-scale reference plants from 150 to 700 MWe. Babcock & Wilcox began working in association with the US-China Clean Energy Research Center program to demonstrate oxy-combustion and other next generation carbon-friendly technologies as part of the Advanced Coal Technology Consortium (CERC). The CERC program was a collaboration between the DOE and Chinese Ministry of Science and Technology. B&W served as an advisor on the 3 MWt oxy-combustion demonstration at Huazhong University of Science and Technology.

RSAT post-combustion showed incredible promise as the next evolution of CO2 capture. The U.S. DOE selected B&W's best-in-class OptiCap solvent for further testing and verification in the pilot solvent test unit located at the National Carbon Capture Center (NCCC) at utility Southern Company's Gaston Plant in Alabama. Results later proved performance of B&W's OptiCap solvent compared favorably with other commercially ready solvents in areas of regeneration energy, corrosivity and solvent degradation.

This same year, OSU contracted with B&W to perform the design and construction of a pressurized 250 kWt Syngas Chemical Looping System at the NCCC.

Babcock & Wilcox played an integral role in the proposed FutureGen 2.0 project for a 200 MWe repowering project at the Meredosia Power Plant, Illinois.

B&W collaborated with Air Liquide of France to participate in a comprehensive testing campaign conducted by Total in France, to gain in-depth knowledge of oxy-combustion technology.

As part of the Phase I activities to establish next generation technologies, B&W received a grant from DOE to perform a techno-economic analysis of a 550 MWe Coal Direct Chemical Looping plant. By 2014, B&W moved to a Phase II project to design, build and demonstrate the CDCL technology at a 250 kWt capacity.

U.S. DOE and Ohio Development Service Agency funded B&W for the performance study of a 4 x 2.5 MWe pre-FEED coal direct chemical looping (CDCL) plant. As part of the program, we performed additional testing at the 250 kWt CDCL pilot facility where sustained operation with coal was demonstrated.

In 2018, the DOE funded a Phase I, feasibility study of 10 MWe pilot facility at an Ohio municipal plant.

OSU and B&W continued to work together to further advance chemical looping technology.

B&W carbon capture technologies are explored for power and industrial applications.

B&W's oxy-coal combustion technology, is ready for near commercial-scale validation which will lead to full-scale commercialization and deployment. RSAT post-combustion technology is ready for demonstration with global partners. Chemical looping stands tall as an advanced CO2 capture and greenhouse gas reduction technology.