Decarbonization and moving to net-negative

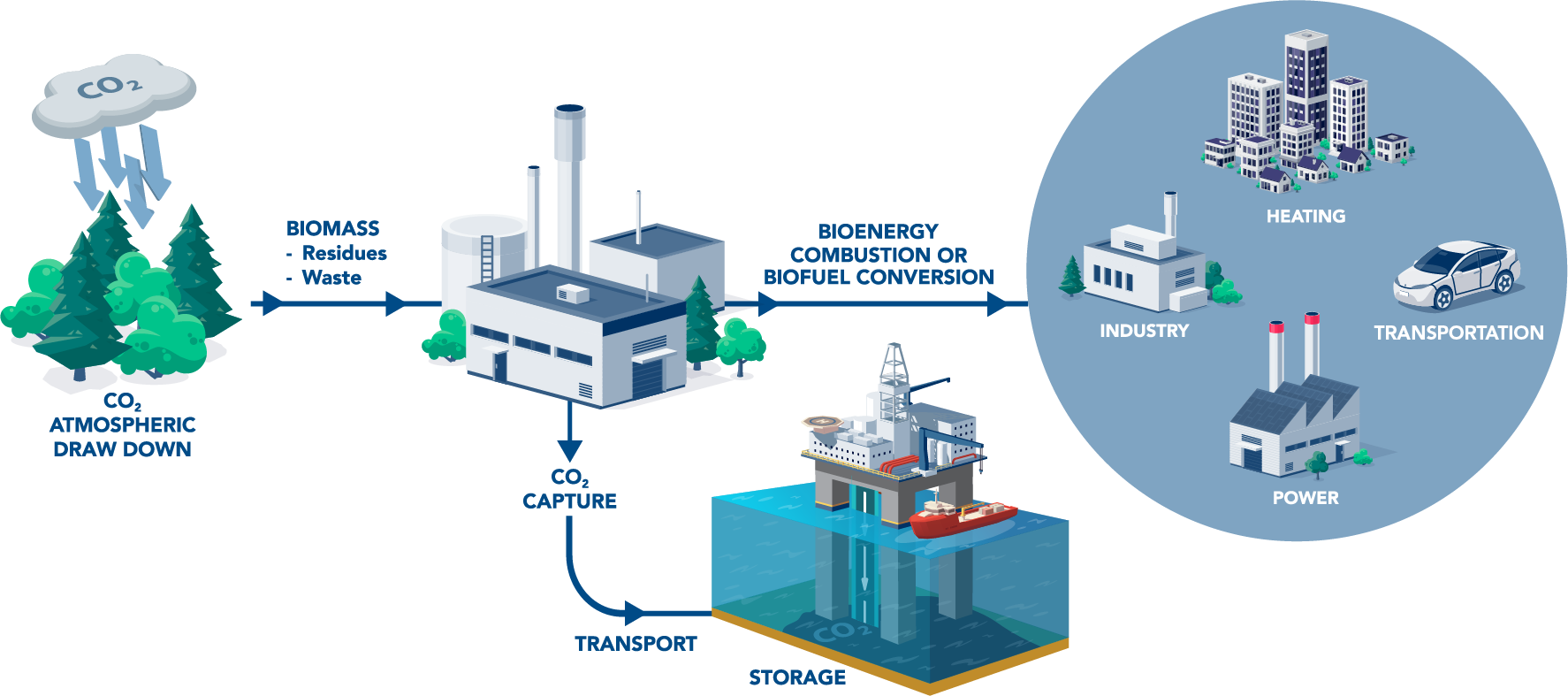

Negative carbon impact technologies provide an innovative means to meet the world’s climate goals. By combining traditional bioenergy production with carbon capture and sequestration technologies (known as BECCS), energy can be produced with a net-negative carbon intensity (CI) output.

How? Plants absorb carbon dioxide from the atmosphere. Calculating the amount absorbed along with sequestration of the CO2 when the biomass is used as a fuel for energy production provides a net result of less than zero carbon intensity.

As a highly scalable technology, BECCS is an emerging innovative solution to decarbonize emission-intensive industries and enable negative carbon emissions from energy production.

Highlights/Overview of BECCS

- Negative emissions technologies provide an innovative means to reaching worldwide climate goals

- Process of capturing and permanently storing CO2 from biomass energy generation

- Carbon neutral: plants absorb CO2 from the atmosphere as they grow, offsetting CO2 emissions released when biomass is combusted

- Carbon negative: removing CO2 from carbon cycle (capture and sequestration)

- As a highly scalable technology, BECCS is positioned to play a key role in this effort

When properly implemented, BECCS not only provides benefits associated with net zero carbon intensity, but may further enable access to beneficial credits/offsets from:

- 45Q carbon sequestration credit via the Inflation Reduction Act (IRA)

- 45Z and 40B clean fuel production credits via the IRA

- 45V clean hydrogen production tax credits via the IRA

- Meeting low carbon fuel standard (LCFS) when power/steam is used to produce electrofuels, or eFuels

- Additional revenue through monetization of carbon-negative offset credits for ESG

Proven bioenergy project experience

B&W’s experience utilizing biomass for energy production is well-proven. Our demonstrated experience covers a wide range of fuels and technologies for utilizing biomass to produce steam for both utility and industrial customers including:

- Bubbling fluidized-bed (BFB) boilers

- Stoker-fired boilers

- Combustion technologies (grates, burners)

- Stoker feeders (air spouts, screw feeders, vertical feeders)

BECCS technology for power and steam

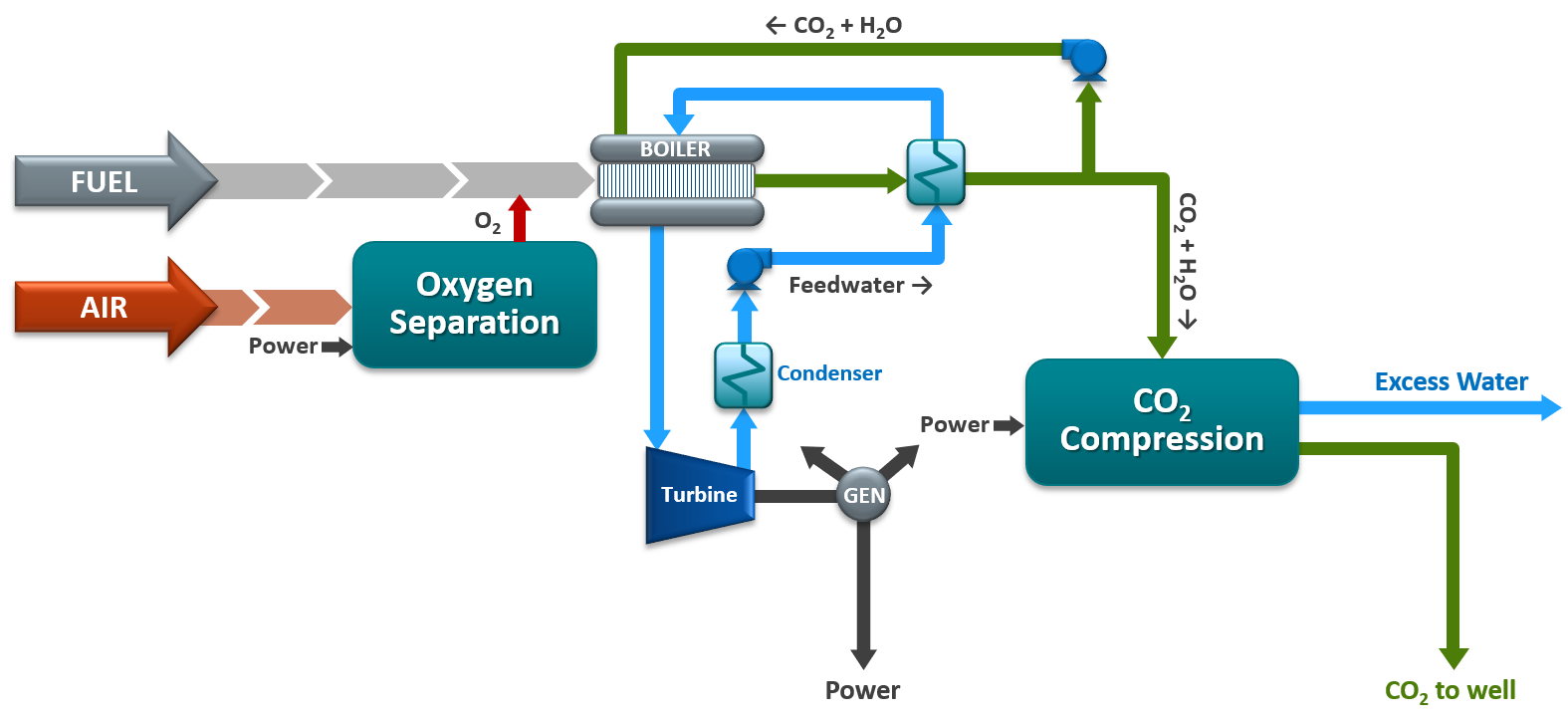

In one innovative application, B&W’s biomass-fired BFB boiler technology is combined with B&W’s OxyBright™ oxygen combustion technology. Wet waste biomass such as forest litter, construction and demolition waste, or agricultural byproducts, can fuel our bubbling fluidized-bed boiler.

The boiler combustion air is replaced with nearly pure oxygen. A portion of the CO2-rich flue gas is recirculated to the boiler, substituting CO2 for the nitrogen in the furnace. The result is a flue gas comprised primarily of CO2. The balance of the non-recirculated flue gas is cleaned using particulate and sulfur removal systems, then sent to a compression purification unit (CPU) to produce a high-purity CO2 stream suitable for sequestration.

The combined use of biomass for the fuel and carbon sequestration results in a source of energy that is carbon negative. An example is B&W’s contribution to Project Cyclus. B&W will provide the technology to power Fidelis’ state-of-the-art, 73,000-barrel-per-day Grön Fuels facility, which is designed to produce a range of clean fuels with a net-negative CO2 footprint.

Utilizing waste-to-energy (WTE) as the combustion technology is another viable option. Municipal solid waste (MSW) is typically considered to contain approximately 50% biogenic material. Although not as net-negative as using 100 percent biomass for the fuel, MSW still holds promise to provide the benefits of net-negative carbon intensity power production in those applications.

With conventional boiler combustion technology, B&W’s SolveBright solvent absorption technology can be utilized as a post-combustion carbon capture solution. B&W’s innovative design allows solvent flexibility to provide solutions which are adapted to customers’ unique applications.

BECCS technology for hydrogen

Another approach to net-negative energy production using biomass as the fuel source is with B&W’s BrightLoop chemical looping technology. A unique advantage of this process is its ability to use solid fuels to produce a range of possible outputs, including hydrogen. Our technology is capable of producing a stream of nearly pure hydrogen in addition to a stream of nearly pure CO2.

Using biomass as the source feedstock for B&W’s BrightLoop process, combined with the inherent CO2 isolation and sequestration, a net-negative CI energy production is possible.

| Technology Potential | |

|---|---|

| Technology | Modeled Result |

| OxyBright with B&W’s biomass-fired BFB Boiler | Carbon negative electricity with a –2,500 g CO2e/kWh carbon intensity |

| OxyBright with B&W’s WTE Technology | Carbon negative electricity with a –1,000 g CO2e/kWh carbon intensity |

| BrightLoop for hydrogen production with biomass as the fuel | Carbon negative hydrogen production of –14 kg CO2e/kg H2 (–118 g CO2e/MJ H2) |

Notes:

- Calculations consider CO2 emissions for biomass harvesting and transportation to plant site.

- CO2e = CO2 equivalent