Waste-to-Energy Technologies

Providing clean, efficient and renewable energy from waste

Our capabilities of turning waste into energy include the complete plant scope of combustion grates, state-of-the-art boilers, fuel and ash handling systems, and emissions control technologies. As a leading waste-to-energy company, B&W and our subsidiaries have more than 155 years of experience in designing, supplying and servicing some of the world’s cleanest, most efficient energy and environmental systems.

Complete Plant Scope

- DynaGrate® waste combustion grate

- DynaFeeder® fuel feeder

- DynaDischarger® ash extractor

- Project Summaries: Amager Bakke, Kelvin and more

- Vølund® waste technology

- Safety innovations

- Diamond Power® sootblowers

- GMAB™ flue gas treatment and energy recovery

- SPIG™ air-cooled condenser

- Integrated carbon capture

DynaGrate® Combustion Grate

Advanced design features for high energy recovery, fuel flexibility and low maintenance costs.

Its unique design delivers a wave-like longitudinal movement which results in optimal turnover of the fuel bed.

- Optimal fuel-bed agitation enables uniform and efficient combustion with a high burnout rate

- Fuel flexibility along with biomass co-firing capability

- No contact between moving parts limits wear and lowers spare part cost

- Ability to process waste containing metals

- Integrated air or water cooling ensures stable operation and high availability

Vølund® Combustion Grate

Dependable and proven performance

For simplicity of design combined with robustness of operation, the air-cooled Vølund™ grate is one of the most dependable energy-from- waste grates available. It’s ideal for fuels with a wide calorific waste range. With auxiliary burner support, the grate can handle wet waste, common during rainy seasons. Learn more>>

DynaFeeder® Fuel Feeder

Provides a continual and even fuel layer across the entire combustion grate for steady energy output and maximum efficiency. It is tolerant and robust with design features that allow servicing during operations.

DynaDischarger® Ash Extractor

With mechanical design features for high availability, fewer unplanned stops and safe service access.

The DynaDischarger ash extractor is compatible with any grate, regardless of manufacturer. It can be retrofitted during a normal service shutdown period.

- Accommodates larger objects and has fewer unplanned stops due to reduced blockage risk

- Ash level sensors alert operators of an abnormal rise in ash levels to allow timely corrective action

- Safe and quick removal of clogged items

- Compatible with any combustion grate

Project Summary

Amager Bakke, Copenhagen, Denmark

This iconic urban energy-from-waste plant is also a ski slope and center for recreation

- Processes 400,000 tons/year unrecyclable waste

- Generates 63 MW of electricity, and district heating for 120,000 homes

- In the heart of Copenhagen for sustainable waste collection and optimal energy distribution

- NOx emissions well below EU requirements

Project Summary

Kelvin Plant, West Bromwich, UK

See how the DynaGrate, DynaFeeder and DynaDischarger were installed at this waste-to-energy plant

- Will process 395,000 tons/year of unrecyclable waste

- 135 MWth waste boiler will generate 47 MW gross baseload electricity powering 95,000 homes

Energy-from-Waste Boiler Designs

Three major designs are used in waste to energy plants: 1) single-pass furnace, 2) multi-pass furnace with vertical convection pass, and 3) multi-pass furnace with a horizontal convection pass.

B&W has proven experience with designing and building all three variations, with the choice of design determined by the application. All three designs feature a furnace that is strategically arranged over the grate to control gas flow and maximize heat absorption, and thus, maximize efficiency. B&W designs the flue gas flow path to provide reasonably uniform cross-section flow and temperature distributions by using physical and/or numerical computational fluid dynamics (CFD) modeling, and empirical data.

Water-Cooled Wear Zones

Water-cooled wear zones are an innovative, efficient and economical way to improve operational accessibility and productivity for waste-to-energy plants. The water-cooled zones reduce the area of uncooled refractory in the furnace of our waste-to-energy boilers.

- Reduces maintenance costs by reducing refractory volume

- Constructed to ensure stability and withstand pressure

- More heat absorption in the water-cooled wear zone provides additional plant output

- Can be installed during a standard maintenance outage

Adaptive SNCR for Optimized Boiler NOx Reduction

The selective non-catalytic reduction (SNCR) system from B&W provides optimized nitrogen oxides (NOx) control while maintaining proper boiler operation. By knowing the detailed design criteria of the SNCR system and integrating this into our computational fluid dynamics (CFD)-based boiler design process, we optimize boiler operation and NOx emissions. Read this project summary to learn how our adaptive SNCR was integrated into the plant upgrade at Filborna, Sweden.

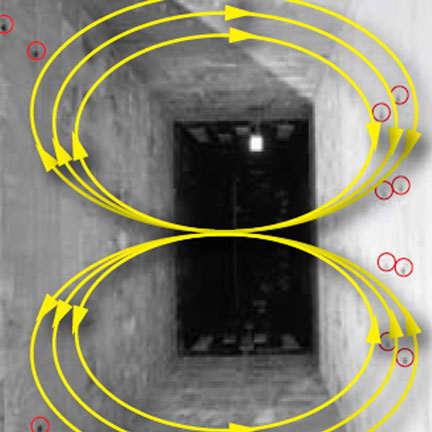

VoluMix Systems

Proper, turbulent mixing of the flue gases in the boiler furnace provides a better combustion process and burn-out in the gas phase.

With the VoluMix™ system, all primary air passes through the narrow gap between the grate bars, creating a strong, turbulent combustion zone. The system is installed at the inlet of the first pass.

VoluMix ensures very low carbon monoxide (CO) and total organic carbon (TOC) content in the flue gas.

Advantages of VoluMix include:

- Good mixing and combustion conditions in the furnace – gas-phase burnout

- Staged combustion makes it possible to reduce the formation of fuel NOx

- Avoidance of hot spots in the furnace and boiler which would speed up corrosion

- Obtaining turbulent conditions for optimum burnout–low CO levels

- Uniform temperature and velocity distribution in the convection passes to maximize heat transfer and residence time

- Basis for low excess air resulting in high overall thermal efficiency

- Eliminates the need for flue gas recirculation, saving fan investment cost, as well as operation and maintenance costs

Inconel® Cladding for furnace corrosion protection

Since the combustion products from municipal solid waste fuels are very corrosive, some form of corrosion protection is needed. Typically, the protection area will encompass all four furnace walls up to a certain elevation.

A proven method of corrosion protection is utilizing Inconel® weld overlay on lower furnace wall sections of municipal solid waste boilers. In fact, B&W pioneered the use of this method for lower furnace protection as well as other corrosion-susceptible areas.

B&W has in-house capability to apply Inconel cladding in a continuous welding process at our production facility in Esbjerg, Denmark. The spiral welding machine can process up to 8 tubes at the same time at lengths up to 12 meters. Watch the video to see how we do it.

Health, Safety and Sustainability

B&W Renewable's waste-to-energy operations are ISO 45001 certified. Our goal is to continually improve our work environment by managing and controlling the risks that exist at the workplace, at our own production facility in Esbjerg, at our offices, and when working on-site at clients’ plants. Also, health and safety are engrained in B&W work culture via the Target Zero program. It reflects our commitment to the overall safety of each employee.