B&W: The worldwide leader in flue gas pre-treatment technologies for post-combustion carbon capture

With the world’s continued focus on decarbonization, post-combustion carbon capture opportunities and installations are expected to increase exponentially.

Solvent-based scrubbing technologies, like B&W’s SolveBright™ process, often require reductions in various pollutants found in the incoming flue gas. Pre-treatment of the flue gas is vital for the operation and economics of the process to result in the optimum effectiveness of the carbon capture technology. Even if your plant is currently meeting all required emissions levels, further reduction may be necessary to meet the requirements of the selected solvent-based scrubbing technology.

As innovators and experts in providing a wide range of emissions control solutions, B&W can be your trusted partner to integrate the necessary environmental technologies into your carbon capture system. We can supply additional emissions control equipment or modify one or more of your existing flue gas cleaning system(s).

Whether or not you choose our SolveBright post-combustion technology for your carbon capture project, turn to us for optimal flue gas pre-treatment solutions.

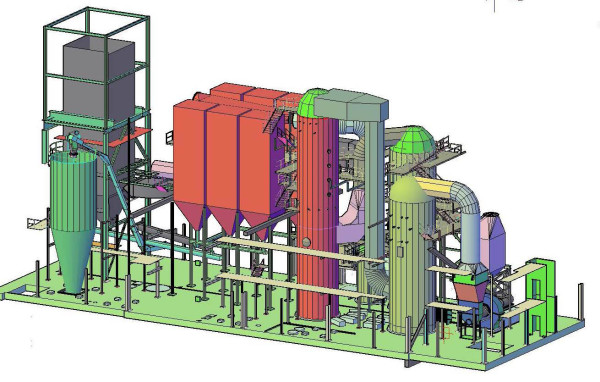

Wet Scrubber Installations

Dry Scrubber Installations

Wet ESP Installations

Dry ESP Installations

Sorbent Injection Installations

Fabric Filter Installations

SCR Installations

Flue Gas Condensation Installations

Hover mouse over the incoming flue gas constituent to see the related pre-treatment technology.

Effective pre-treatment for optimal CO2 scrubbing

All acid gases will degrade the solvents used in a post-combustion carbon capture system. Therefore, it’s imperative that the levels of sulfur dioxide (SO2), sulfur trioxide (SO3), hydrogen chloride (HCl), and hydrogen fluoride (HF) within the flue gas be reduced prior to entering the CO2 absorber.

SO3 is a particular concern as it can form aerosols which absorb the solvent and pass through the CO2 scrubber leading to high concentrations of solvent exiting the system. This could result in solvent emissions being higher than regulated values while also adding to operating costs since the solvent make-up rate will increase.

Other pollutants can also pose problems. Nitrogen oxides (NOx), specifically NO2, are also detrimental for the solvent and can lead to hazardous degradation products in the process. CO2 scrubbing operation may also improve when particulate matter is removed from the flue gas prior to the scrubbing process.

Applications and technology expertise

All our emissions control technologies can be provided on new equipment installations or as upgrades to existing systems. In addition to the extensive emissions control technologies we’ve developed in-house, through acquisitions and licenses we can also provide technologies from some of the most well-known brands in the industry, including: Hamon Research-Cottrell, Joy Environmental, Joy Western, PrecipTech, FLS, Buell, BHA and GE, among others.

All our emissions control technologies can be provided on new equipment installations or as upgrades to existing systems. In addition to the extensive emissions control technologies we’ve developed in-house, through acquisitions and licenses we can also provide technologies from some of the most well-known brands in the industry, including: Hamon Research-Cottrell, Joy Environmental, Joy Western, PrecipTech, FLS, Buell, BHA and GE, among others.

We offer complete construction capabilities as well as aftermarket parts and field services.

B&W:

The worldwide leader in flue gas pre-treatment technologies

for post-combustion carbon capture