Success Stories

From The Leader in Clean Power Production Technologies

Vølund® Waste-to-Energy Technology

Kelvin Waste-to-Energy Plant, West Bromwich, England

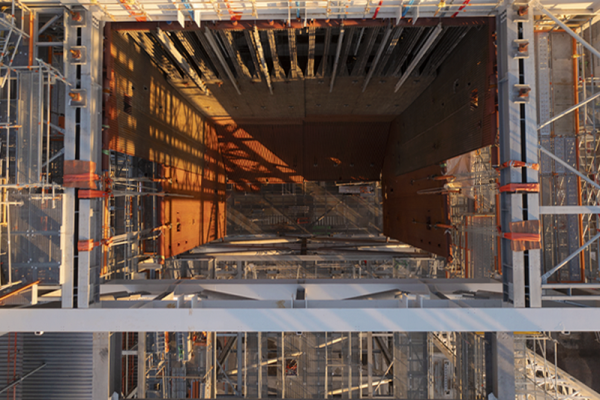

12m x 13.5m DynaGrate combustion grate at the Kelvin energy-from-waste facility.

Kelvin is a waste-to-energy (WTE) facility now under construction in Sandwell West Midlands, just outside Birmingham, U.K. When operational, it will divert 395,000 tonnes of non-recyclable household and business waste from landfill or export overseas. The residual waste will be used to generate 44 MW (gross) of baseload energy, equivalent to the needs of more than 95,000 homes.

One of the ten modular DynaGrate sections being lifted into place.

Owned by Enfinium, a provider of WTE facilities throughout the U.K., the Kelvin plant will utilize state-of-the-art steam generation and combustion technologies from Babcock & Wilcox Renewable (B&W). Working with Acciona as the engineer procure- construct (EPC) contractor, the plant features the largest WTE boiler ever supplied by B&W (at the time of installation).

Scope of Supply

B&W will provide the combustion equipment and boiler design, including:

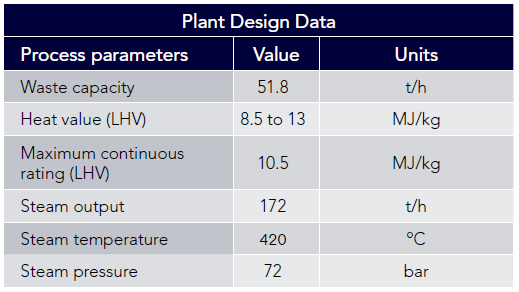

View looking down into boiler furnace.

- Air-cooled DynaGrate® combustion grate

- DynaFeeder® waste fuel feeder system

- DynaDischarger® furnace ash extractor

- Water-cooled wear zone in furnace

- VoluMix™ secondary air system, including fuel bed ignition control

- Advanced flame front control

- Vølund® boiler with multiple pass furnace, horizontal convection pass and economizer

- Boiler cleaning with Diamond Power® Hydro Shower™ automatic sootblower and rapping system

- Adaptive selective non-catalytic reduction (SNCR) system for nitrogen oxides (NOX) control

Facility Facts

DynaDischarger ash extractor being positioned under the grate.

- DynaGrate combustion grate will process more than 395,000 tonnes of post-recycled residual waste

- Plant will generate 44 MW (gross) of baseload electricity

- At 135 MW thermal input, this is the largest WTE boiler designed by B&W (at the time of installation)

- Inconel® weld overlay will be utilized in the entire first pass and two thirds of the second pass for increased corrosion protection and minimized slagging

- The project will be executed under the new UKCA (U.K. Conformity Assessment) regulations for product quality

Check Out The Success Story Video!