Green hydrogen production

Discover our electrolyzer and large-scale hydrogen solutions for sustainable energy systemsBenefits of green hydrogen

Green hydrogen (H2) is a versatile energy carrier that can be applied to decarbonize a wide range of sectors. It can be used directly or in the form of its derivatives like e-methanol, e-ammonia, or e-fuels to replace fossil fuels, coal or gas.

Only around 40% of global carbon dioxide (CO2) emissions originate from power generation which can be decarbonized via electrification. The other 60% of CO2 emissions originate from industry, mobility, buildings and others. These can be decarbonized via sector coupling, using green hydrogen and its derivatives to make renewable energy available to those sectors. This is why the production of sustainable hydrogen is such a crucial issue.

Our electrolyzer portfolio: The optimum solution for large-scale sustainable hydrogen production

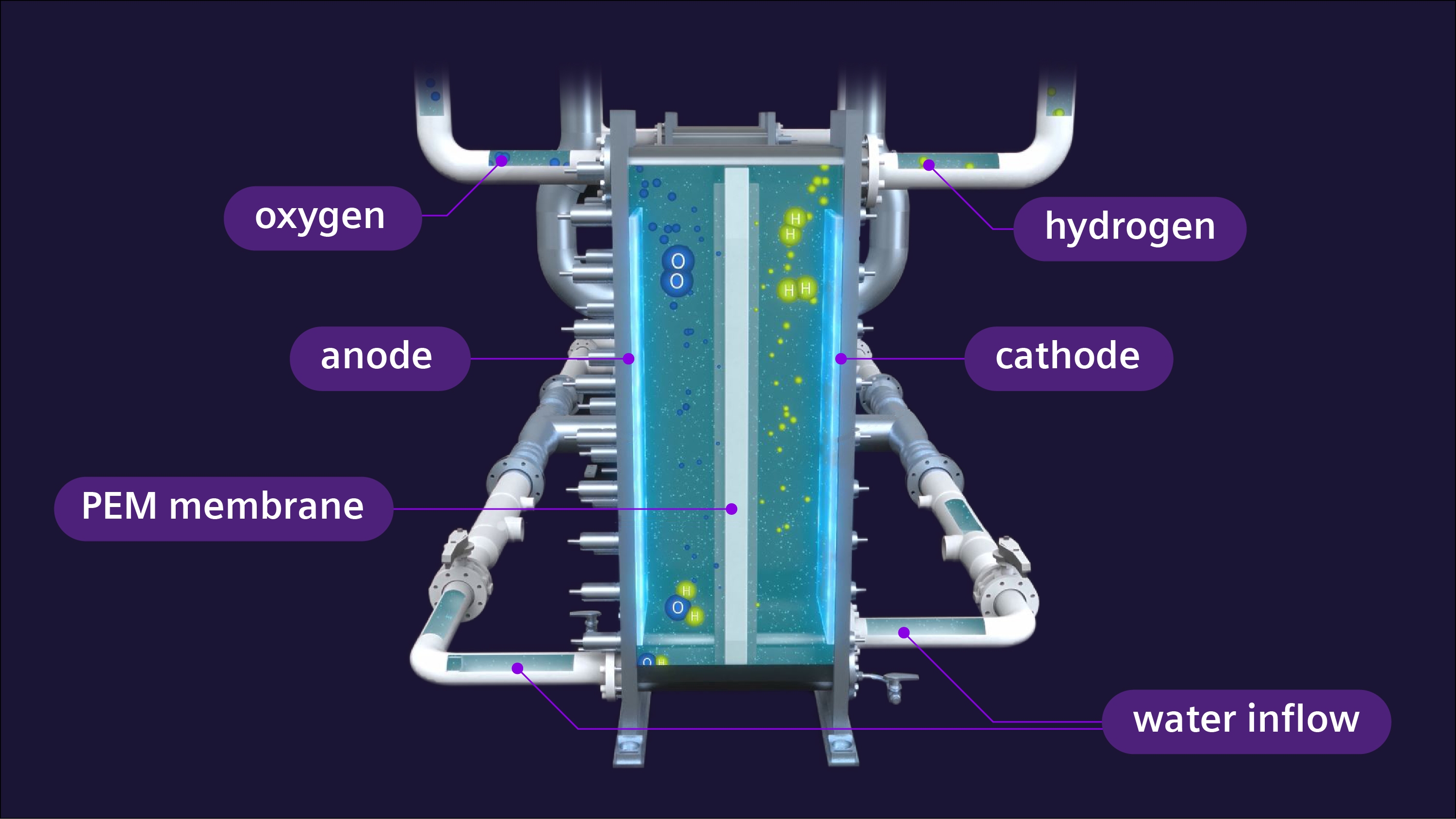

Generating green hydrogen efficiently from water and renewable energy requires high-end technology and innovative solutions — like the Silyzer product family from Siemens Energy. Using Proton Exchange Membrane (PEM) electrolysis, the Silyzer is ideally suited for harnessing volatile energy generated from wind and solar. Combining high efficiency and high power density, our PEM electrolyzers ensure gas products of superior quality. It is easy to operate and requires low maintenance. Using a modular design strategy that splits the electrolysis system into skids, we are able to optimize costs, reduce installation costs, and make the electrolysis system transportable.

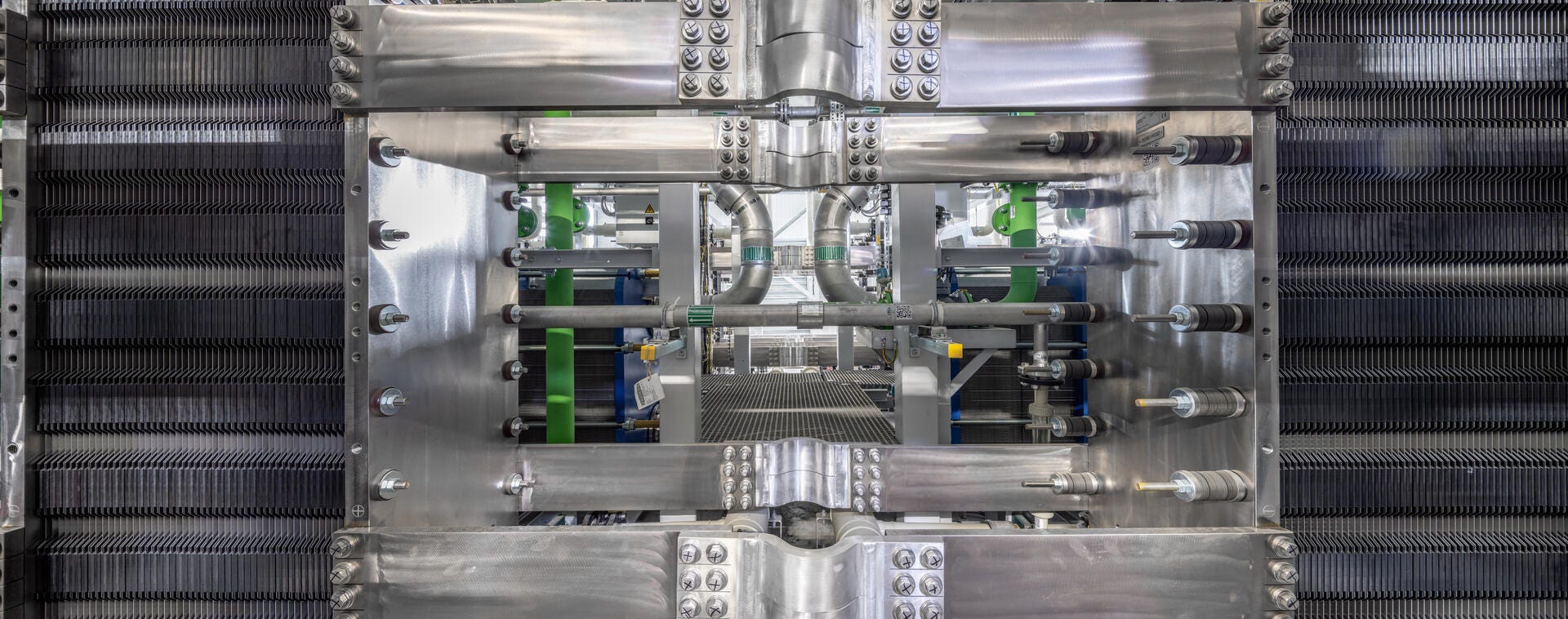

The heart of the PEM electrolyzer, stacks combined in groups. Prefabricated for modular and fast installation on site. The Trailblazer project with our electrolyzer core system.

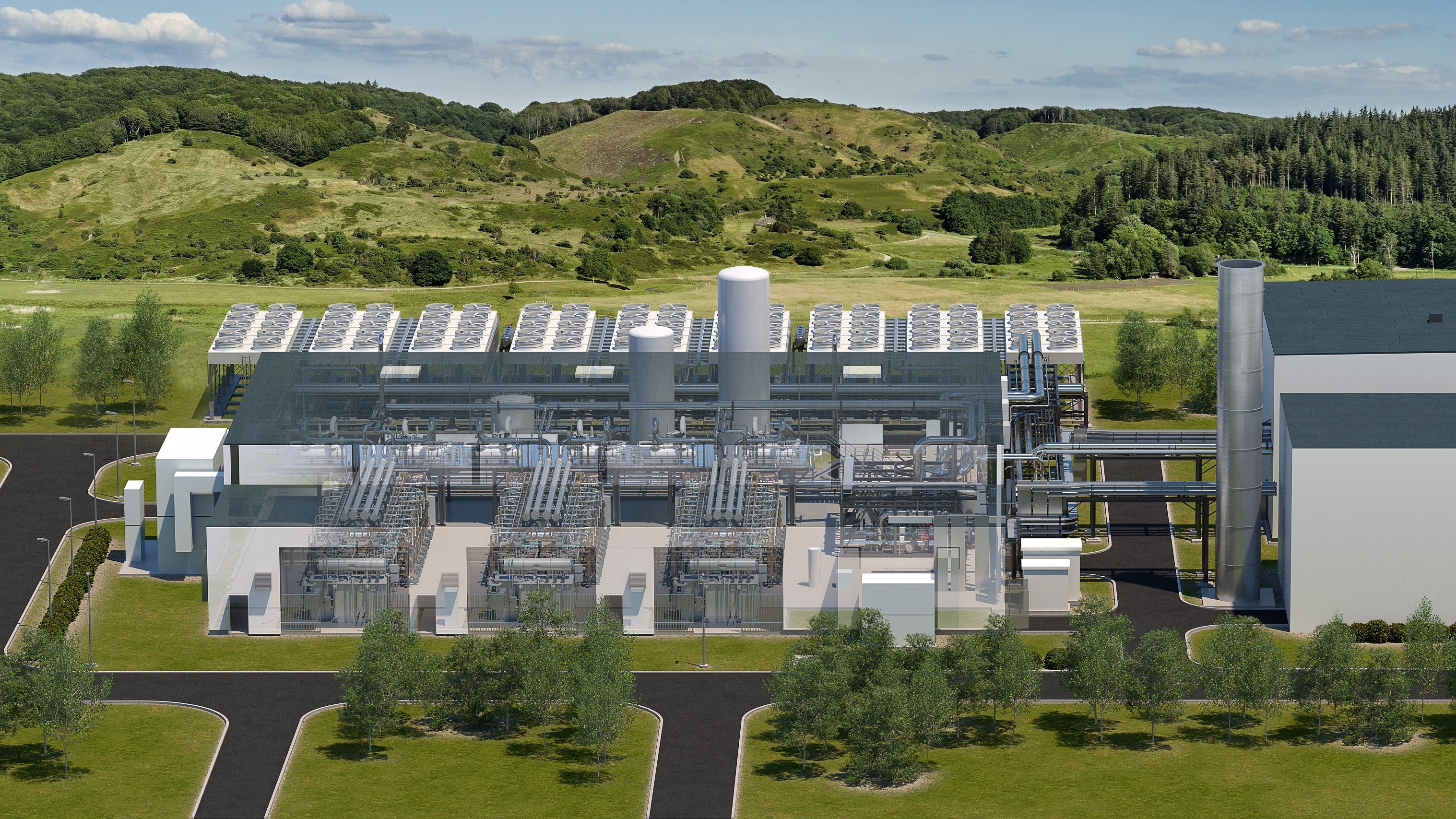

Grid integration and safety first are in our DNA. Transformers and in-house developed rectifier configurations are part of our scope. Upscaling to a higher power level is demonstrated in the 50 MW reference plant as shown in the picture.

With our longstanding experience in the energy industry, we ensure the smooth implementation of large-scale projects and provide comprehensive electrolysis plant services. The modular design of our electrolyzer core system facilitates the design of larger plants up to gigawatt capacity.

Scaling up the capacity of green hydrogen production

Carbon emission targets in the European Union and other industrialized countries will require massive scaling-up and acceleration of renewable hydrogen production and imports – already 20 million tons will be needed in Europe by 2030 to fast forward the energy transition and decarbonization.

That’s why we have joined forces with Air Liquide to create a joint venture dedicated to the series production of industrial-scale renewable hydrogen electrolyzers. In 2023, we started production of electrolysis stacks at our multi-gigawatt electrolyzer facility in Berlin and will ramp up to an annual production capacity of three gigawatts by 2025. The factory will supply stacks to Siemens Energy and Air Liquide for our broad range of customers and serve the rapidly growing market.

The new gigawatt electrolyzer plant in Berlin is highly automated with robotics and digitalization.

Your service partner for green hydrogen production and beyond

Siemens Energy can offer comprehensive services for your electrolyzer plant and energy assets along the entire hydrogen value chain. Our service agreements range from basic maintenance to premium service with state-of-the-art data analysis and can be customized to your needs.

Our combined package of maintenance, support and digital services can ensure reliable and economical operation. You can reduce your risks with our performance guarantees or enjoy total peace of mind with our Operations and Maintenance service program. Together, we will push your clean hydrogen production to the next level.

Our system in the field

Normand'Hy | France

Delivering 12 electrolyzers to Normandy

- Starting in 2026, Air Liquide’s plant in the Port-Jérôme industrial zone will produce 28,000 tons of renewable hydrogen

- 250,000 tones less CO2 per year thanks to 200 MW electrolyzers

- Industrial-scale hydrogen electrolyzer plant to decarbonize industry and mobility

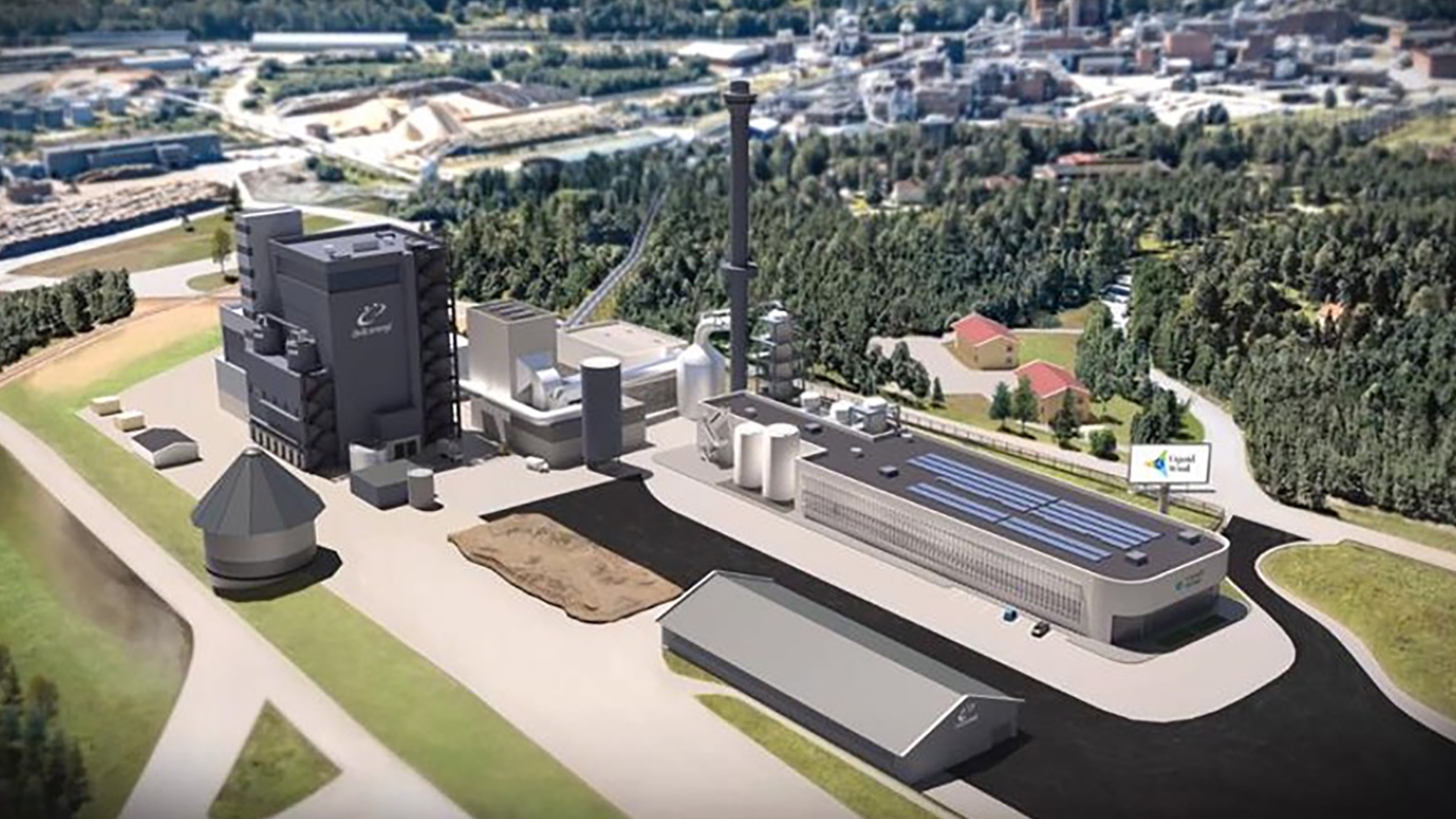

FlagshipONE | Sweden

Blueprint for eFuel production

- Europe's biggest commercial production facility for carbon-neutral marine fuels is being built by the Danish company Ørsted

- At the center of the FlagshipONE plant is a technology package from Siemens Energy with 70 MW electrolyzer capacity

- The plant will be able to generate up to 50,000 metric tons of e-methanol for shipping annually

Hy4Chem-EI | Germany

Hydrogen for the chemical industry

- 54 MW PEM-electrolyzer for BASF's Ludwigshafen site from 2025

- BASF will predominantly use the produced hydrogen as a raw material for manufacturing products

- Annual reduction in CO2-emissions of up to 72,000 metric tons

Kassø | Denmark

Large-scale e-Methanol project

- Starting point into CO2-neutral shipping in large-scale: End users of the e-Methanol will be the shipping company Maersk and the fuel retailer

Circle K among others. - Siemens Energy will implement an electrolyzer plant in the 50 MW range

- European Energy will be responsible for utilizing the electrolyzer in Aabenraa in the Southern part of Denmark

Trailblazer | Germany

Air Liquide to build 20 MW electrolyzer

- Germany's largest electrolyzer connected to an existing hydrogen infrastructure

- Is being developed in Oberhausen within the framwork of the large scale electrolyzer partnership between Air Liquide and Siemens Energy

- Cooperation between Air Liquide and Siemens Energy for European ecosytem for electrolysis and hydrogen technology

Haru Oni | Chile

Fuel from wind and water

- December 2022, first low-carbon fuel has been produced at the integrated and commercial large-scale Power-to-X plant

- Siemens Energy develops and implements this pioneering project alongside several international companies

- The system is expected to produce 130,000 liters of eFuel per year in 2023, followed by a projected 55 million liters by mid-decade and a expected 550 million liters per year two years later

H2Future | Austria

Green hydrogen for steel

- World's first PEM electrolysis facility Silyzer 300 producing 1.200 Nm³ of green hydrogen per hour with 6 MW power demand and a high electrolysis system efficiency of 80%

- Hydrogen for the steel making process: Potential for "breakthrough" steelmaking technologies which replace carbon by green hydrogen as basis for further upscaling to industrial dimensions

- Supply grid services via a highly dynamic power consumption

Your partner for sustainable hydrogen production

With our extensive knowledge of industrial, mobility, and energy sectors, we’re able to provide dependable solutions for our customers in every aspect of green hydrogen production.

You will benefit from Siemens Energy’s decades of experience, global footprint, infrastructure, strong partnerships and manpower available, covering the full energy value chain from renewable power via transmission to hydrogen and Power-to-X production. Moreover, we can help you certify the source of green energy with Clean Energy Certificates.

Are you ready for the green hydrogen economy? We are and we look forward to being your partner for sustainable hydrogen generation.

Good to know

Download Siemens Energy's technical papers and benefit from our expertise.

Power-to-X: On the way to a carbon-free world

The white paper provides an overview of use cases and solution packages for industries, utilities and project developer. Learn more about Power-to-X:

Power-to-X: A closer look at e-Ammonia

Find out more about the economic feasibility, key markets and applications of e-Ammonia around the world in connection with Power-to-X:

e-Methanol: A universal green fuel

In the future, non-fossil e-Methanol will see vast new application fields. This paper focuses on the green hydrogen path, which uses renewable electricity. Learn more:

FAQ – The most common questions on hydrogen

- General

- Produce, store, transport

- Safety

- Electrolysis

- Application

- Energy transition

Hydrogen (chemical symbol H) is a gas. As a molecule (H2), it occurs only in small amounts in nature and it is mainly chemically bound, such as H2O.

Hydrogen is the most abundant element in the universe. 90 percent of all atoms are hydrogen atoms. They add up to three quarters of the total mass in the universe.

Hydrogen converts into a liquid at minus 253 ºC.

Hydrogen has the highest energy density of all conventional fuels by mass: almost three times as high as that of gasoline or diesel. That is one of the reasons why hydrogen is used as fuel for space travel.

H2 Higher Heating Value: 39.4 kWh/kg; H2 Lower Heating Value: 33.3 kWh/kg

By combusting hydrogen, it delivers heat. Used in fuel cells, hydrogen is converted electrochemically to electrical energy.

Hydrogen has been produced and used for more than 200 years. Experience shows that hydrogen can be stored, distributed and converted safely. As early as 1808, the first large-scale use of hydrogen was established for the street lighting system in London.

Hydrogen (H2) can be produced in different ways. For the moment more than 95% of the hydrogen worldwide is produced from hydrocarbons while producing and emitting harmful CO2. A more modern and ecofriendly technology for CO2 neutral production of hydrogen can be offered by electrolysis of water.

Hydrogen can be produced from hydrocarbons by steam reforming of natural gas - often referred to as steam methane reforming (SMR), coal gasification and from an electrolysis process of water (H2O).

Hydrogen can be stored in tanks as a compressed gas or as a liquid. Hydrogen can also be stored in caverns or in the natural gas grid for different applications and if the grid fulfils all technological requirements.

The volumetric energy density of hydrogen at atmospheric pressure is approximately one third of traditional fuels. The volumetric energy density can be increased by compression or liquefaction of the hydrogen gas to store and transport a greater amount of hydrogen.

For hydrogen-powered vehicles, an industry standard of 300 to 700 bar has been established. Vehicles for the transport of compressed hydrogen, so called “tankers”, usually working with a maximum pressure of 200 bar.

Hydrogen can be transported as a compressed gas or a cryogenic liquid. Today, the two main methods for transporting hydrogen (primarily in a gaseous state) are via tanker e.g. tube trailer for road transportation and in gas pipelines (for short distance).

Hydrogen is a non-toxic clear gas. It is not poisonous, has no taste or odor. Using hydrogen as a fuel source with fuel cells does not create fumes, pollute the atmosphere with carbon dioxide or emit nitrogen oxides.

It is not inherently more dangerous than other fuel sources. Hydrogen is flammable and must be handled with care, just like other flammable fuels. To ignite, the hydrogen must be combined with an additional oxidizing agent (air, pure oxygen, chlorine, etc.) in a specific concentration and an ignition source (a spark). If, in a worst-case scenario, the hydrogen ignites, it burns upwards very quickly. It creates no dangerous heat radiation above the accident site, as petrol or kerosene do.

The facilities are designed to be permanently leak proof. Flange connections are designed especially for hydrogen and the number of detachable connections are minimized. Furthermore, in buildings a steady air exchange is ensured and the facilities are equipped with safety valves and pressure reliefs. Additionally explosion prevention zones are designated. In these zones, electrical and other equipment needs to be in accordance with 2014/34/EU (ATEX Directive).

No. Hydrogen can be safely handled and stored as well as transported. The industrial gas industry has done so for over a century.

In contrast to gasoline and natural gas, hydrogen gas has significant buoyancy in atmospheric conditions due to its low density, any leaking hydrogen gas ascends immediately and disperses, which reduces the risk of an ignition in open air.

Water gets split into its components hydrogen and oxygen by means of electrical current.

Electrolysis processes can be categorized as follows: alkaline electrolysis with liquid alkaline electrolytes, acidic electrolysis with a solid polymer electrolyte (as PEM) and high temperature electrolysis with a solid oxide as electrolyte.

PEM electrolysis and alkaline electrolysis systems are available at an industrial scale. The solid oxide electrolysis technology is in an early development phase.

PEM is the abbreviation for proton exchange membrane. This membrane is a crucial part of the electrolytic cell in a PEM-electrolyzer. The membrane separates the anode, where the oxygen is collected, and the cathode, where the hydrogen gas is generated.

The type of the ions which closes the electric circuit

- PEM: H+

- Alkali: OH-

- SOE: O2-

- High gas purity >99,999%

- High dynamics

- High efficiency (>70%)

- High power density

- High life cycle

- Clean (no chemicals, only water and electricity)

10 liter demineralized water is needed for 1kg of hydrogen.

On average 50kWh are necessary to produce 1kg of hydrogen, depending on the efficiency of the electrolyzer and operation mode.

The hydrogen market is divided in three sectors. Mobility, energy and industry with industry being by far the largest consumer today (~90%). In the future a redistribution towards the mobility and energy sector is expected .

Today, hydrogen is an important industrial gas, i.e. for the refining of fuels, for the production of fertilizer and methanol, for the hydrogenation of fats, for steel production, metal processing, as well as in the production of flat glass.

Less than 1kg of hydrogen is needed per 100km.

Passenger car or light duty vehicle fueling takes 3 to 5 minutes.

Hydrogen enables the long-term storage of large quantities of surplus renewable energy. It is allows new ways to use green electricity, i.e. by using hydrogen as substitute for natural gas by feeding it into existing pipelines, as fuel for fuel-cell vehicles or power plants, or as feedstock for the hydrogen processing industry. It opens the possibility to connect energy generation with the industry and mobility sectors, the so called “sector coupling”.

No. Hydrogen will become a substantial and permanent element of a sustainable energy industry.

In the future, hydrogen will be produced to a greater extent using electricity from renewable energy sources. Furthermore, biogas and various fuels like solid biomass will help to produce green hydrogen in the future.

‘Green’ hydrogen is sourced by 100% renewable energy. That means that the needed energy to produce hydrogen by electrolysis has emitted zero emissions. Hydrogen produced from fossil fuels releasing emissions such as CO2, may be referred to as ‘grey’ or ‘brown’ hydrogen. If the emitted carbon dioxide is captured, stored (carbon capture storage) and re-used, it is often called ‘blue’ hydrogen.

Get in touch with our sales support

Do you have any questions? This is your direct line to Siemens Energy Silyzer Team! No matter in which country you are located, we are here to support you. Please use the contact form below to raise your question.