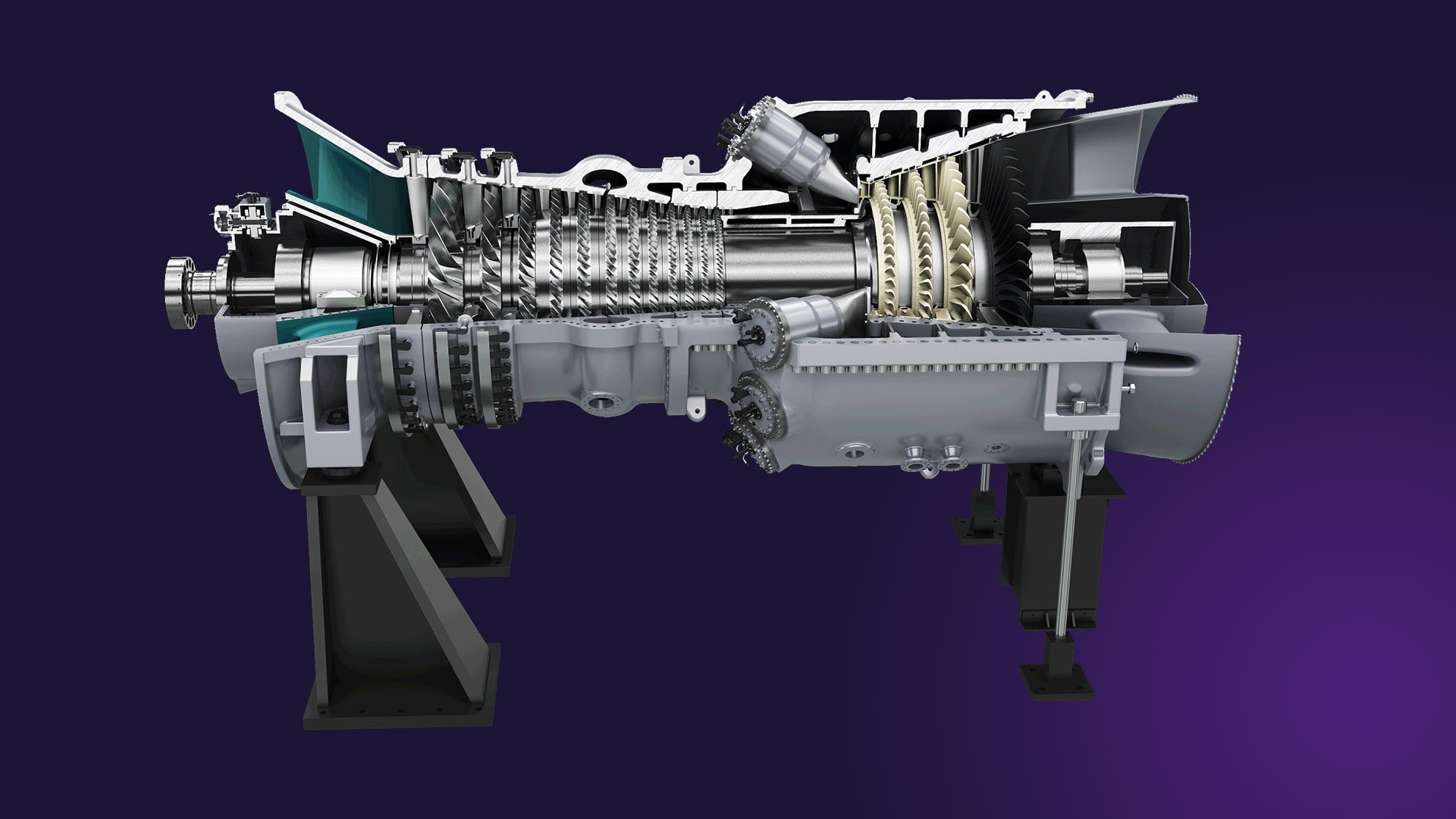

Reliable gas turbines

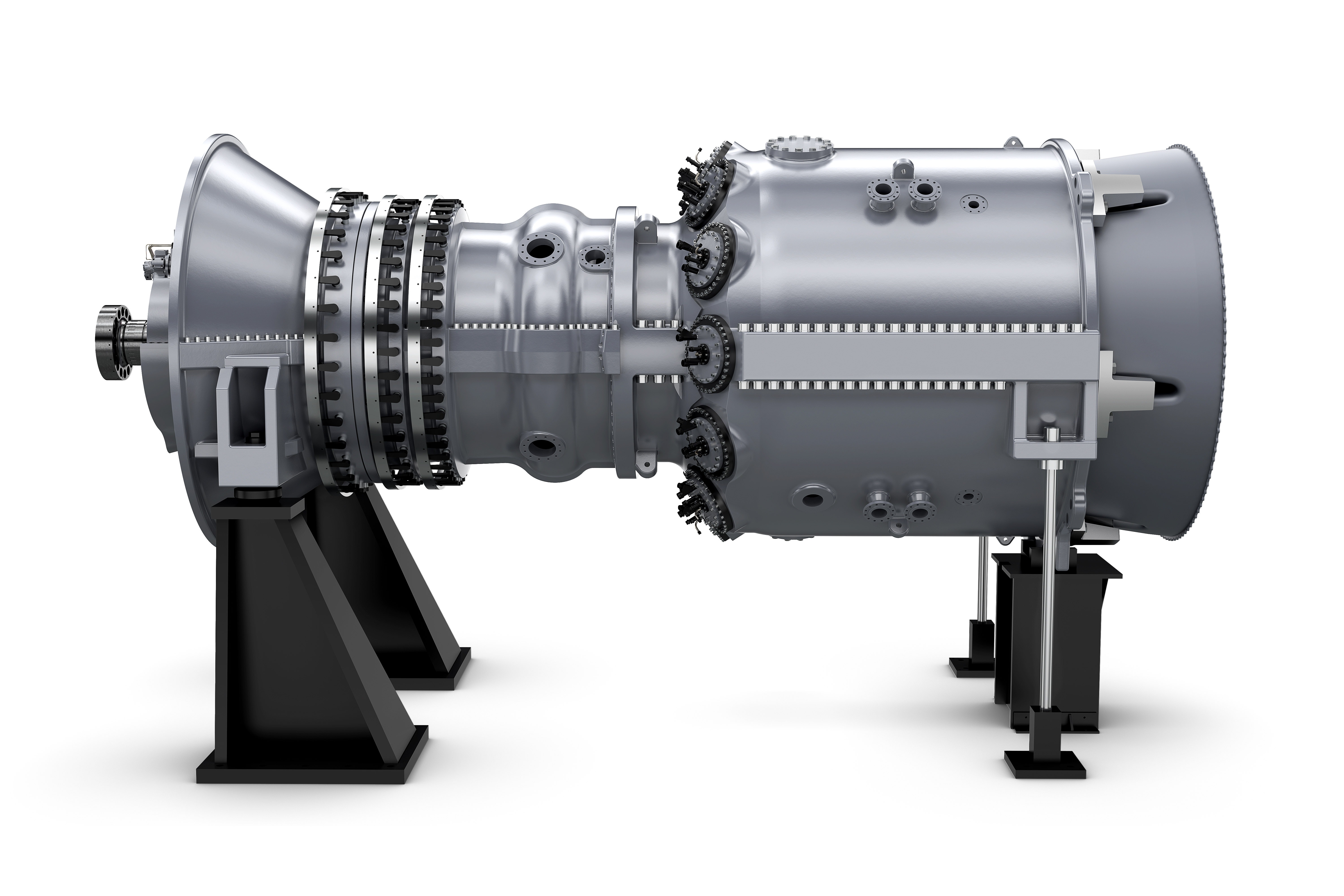

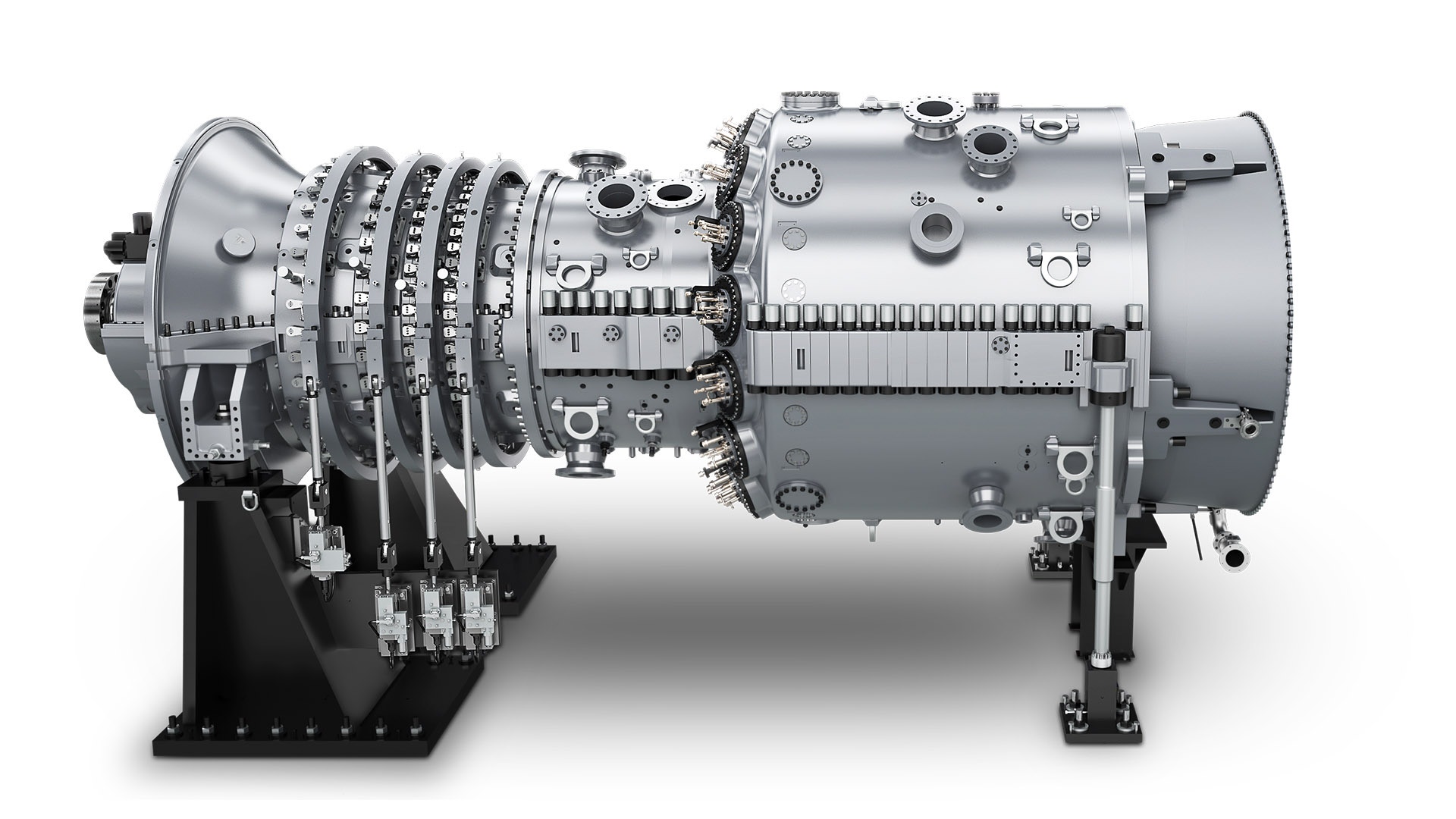

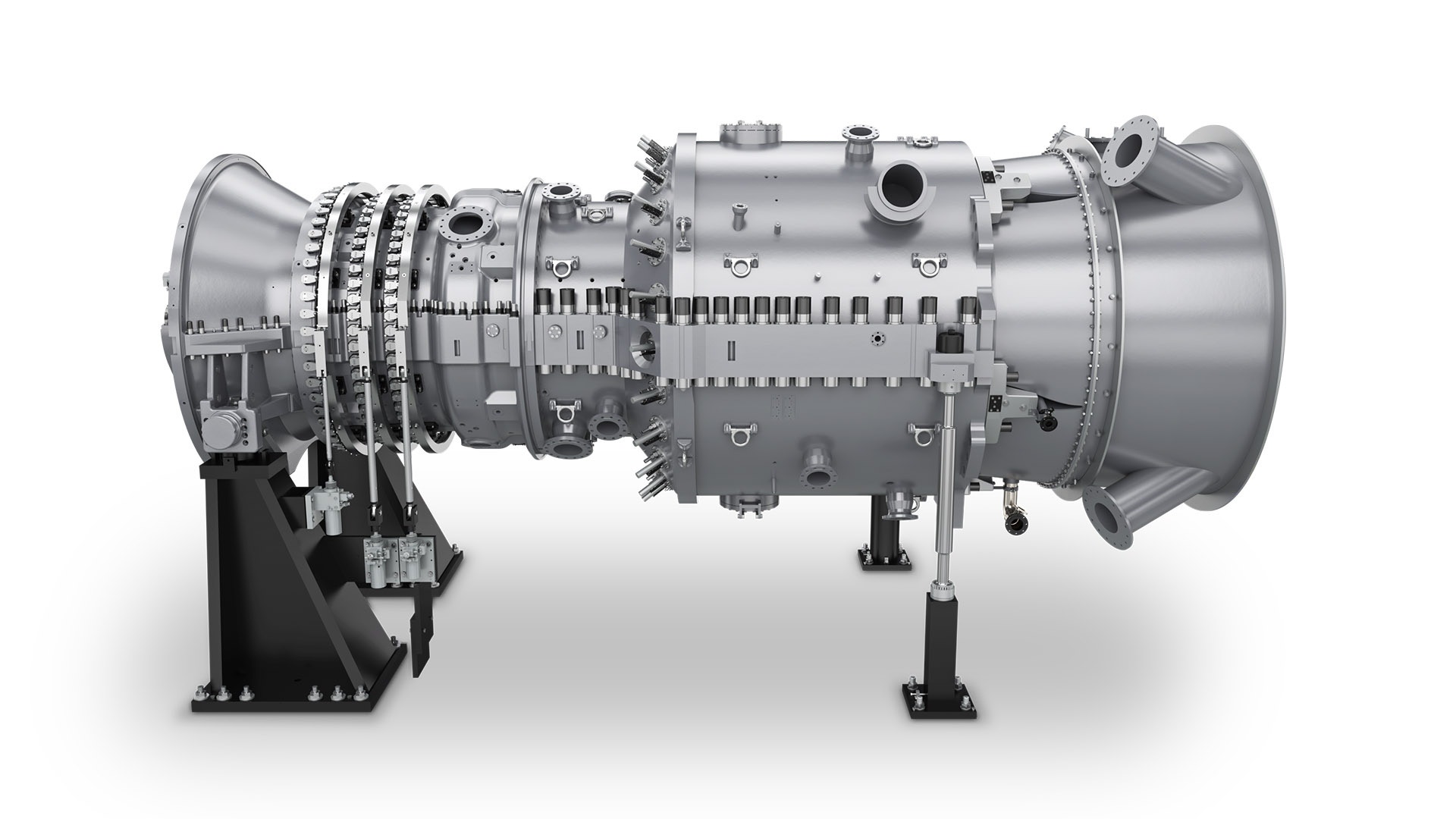

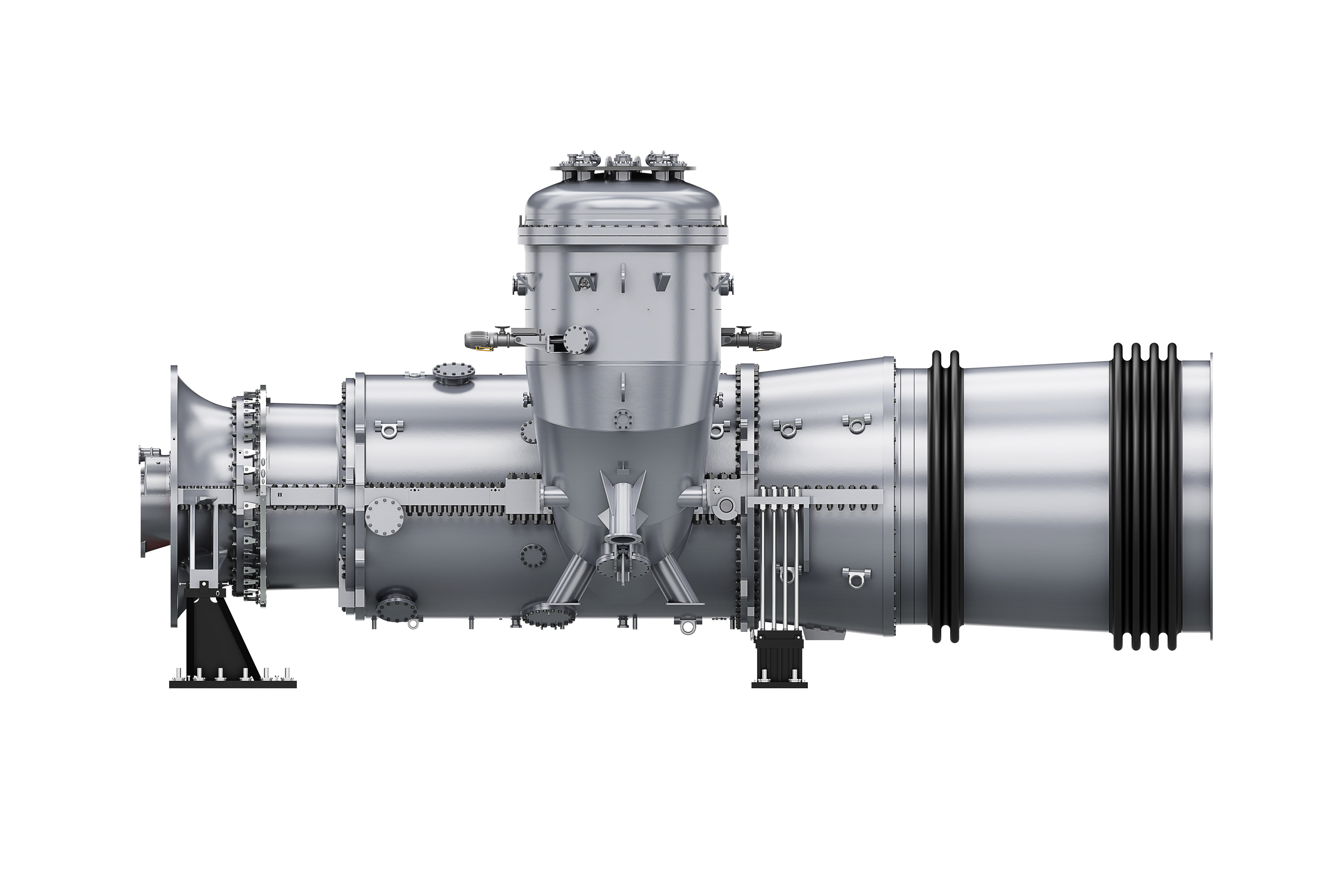

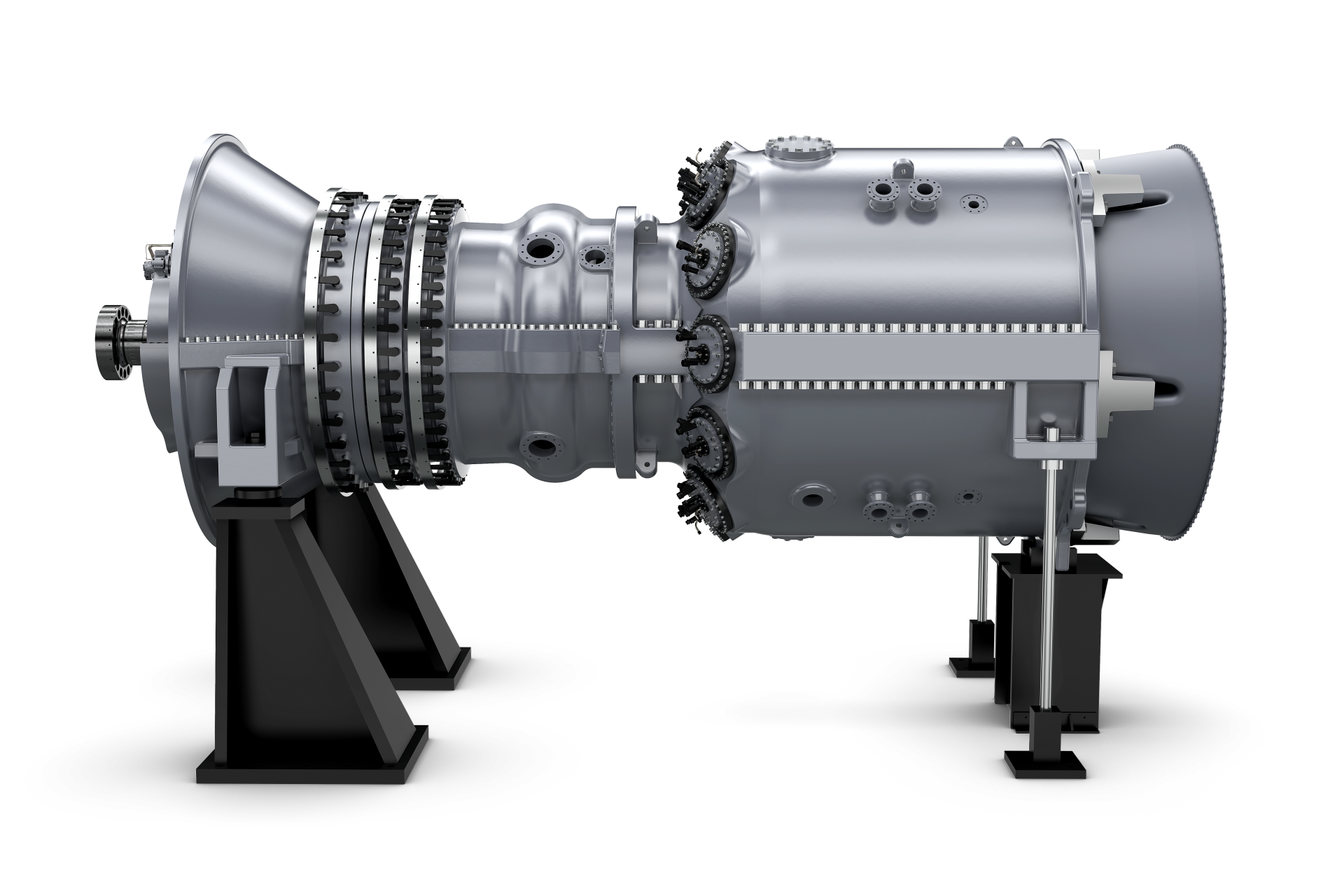

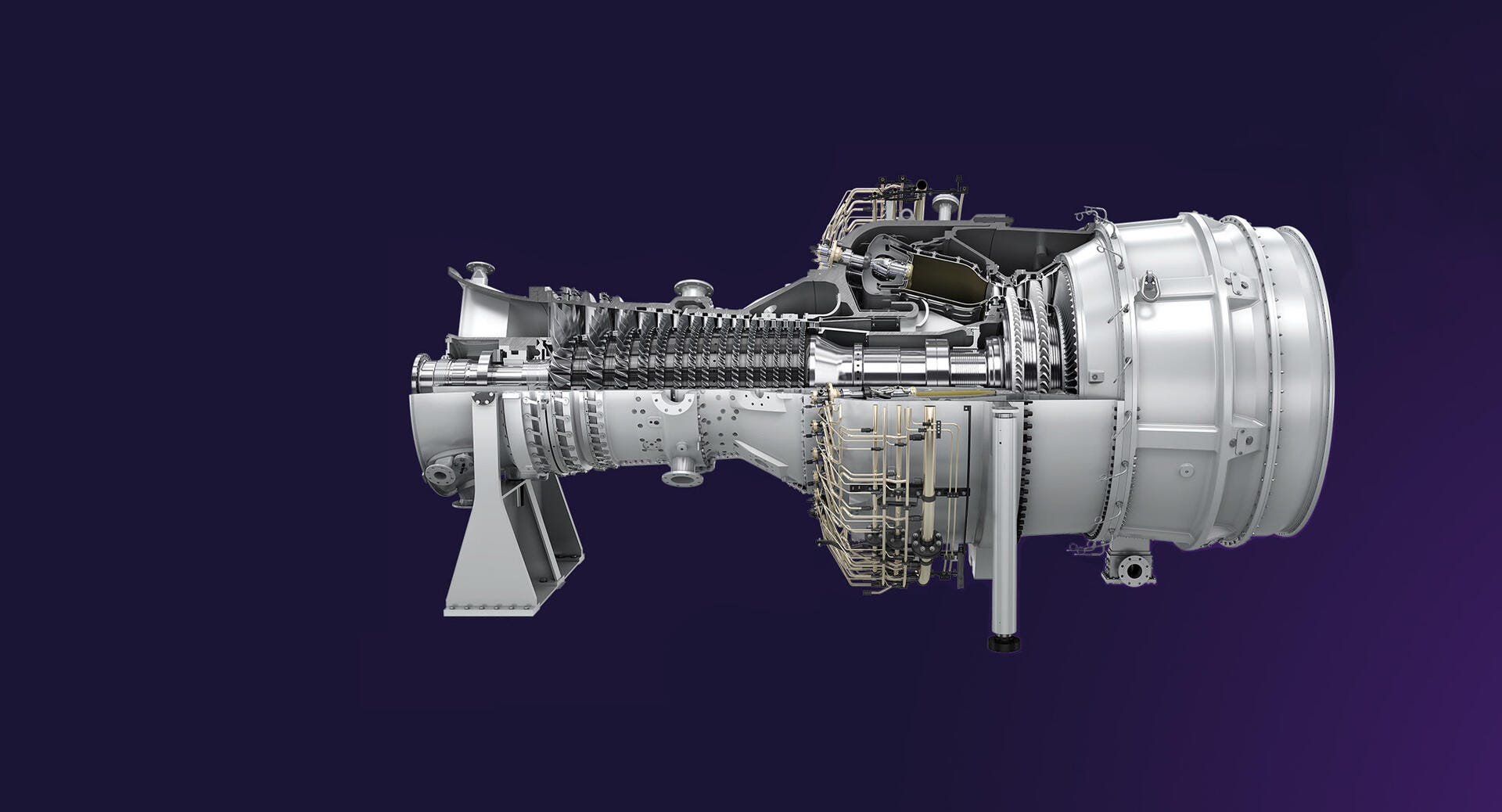

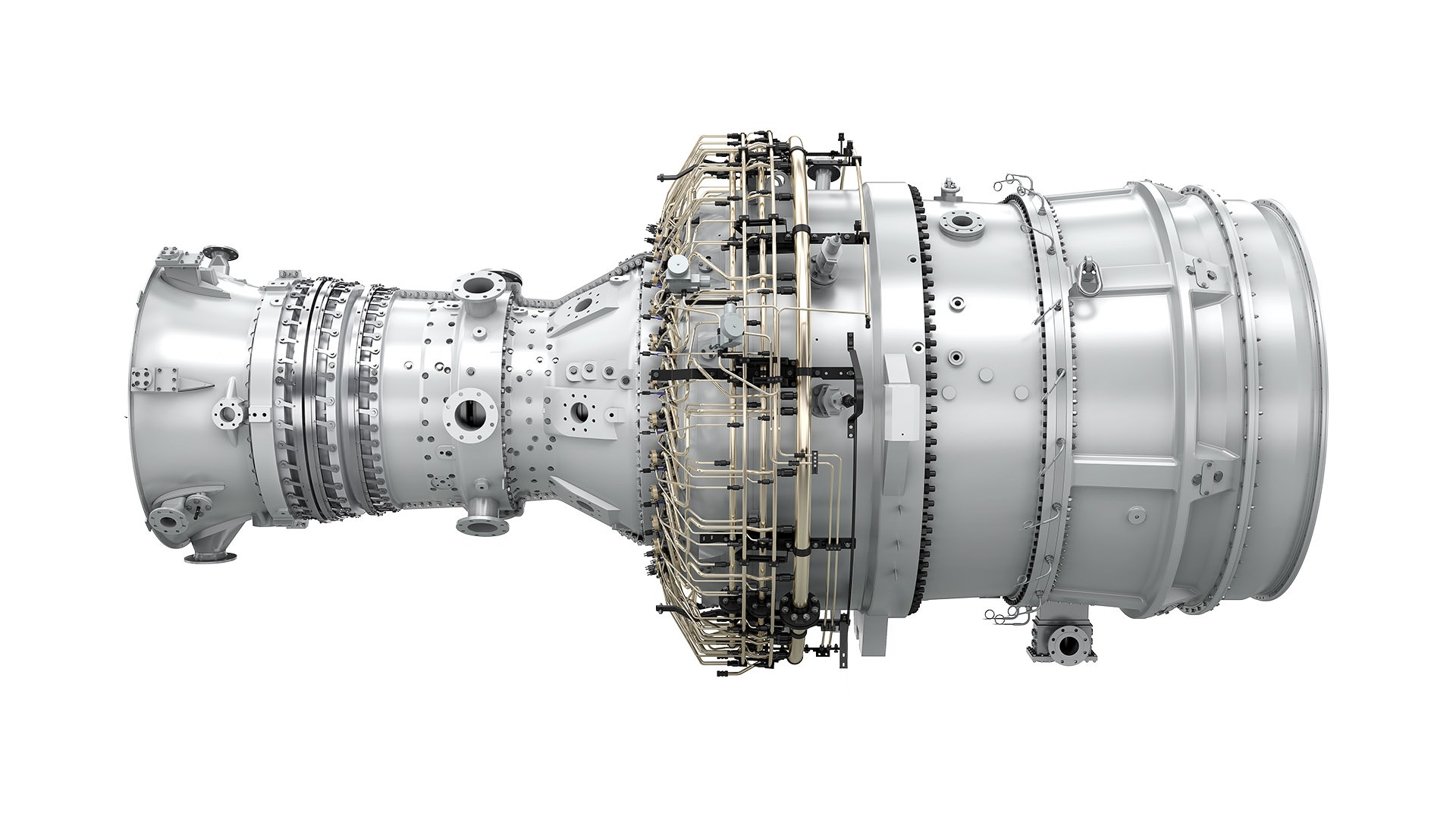

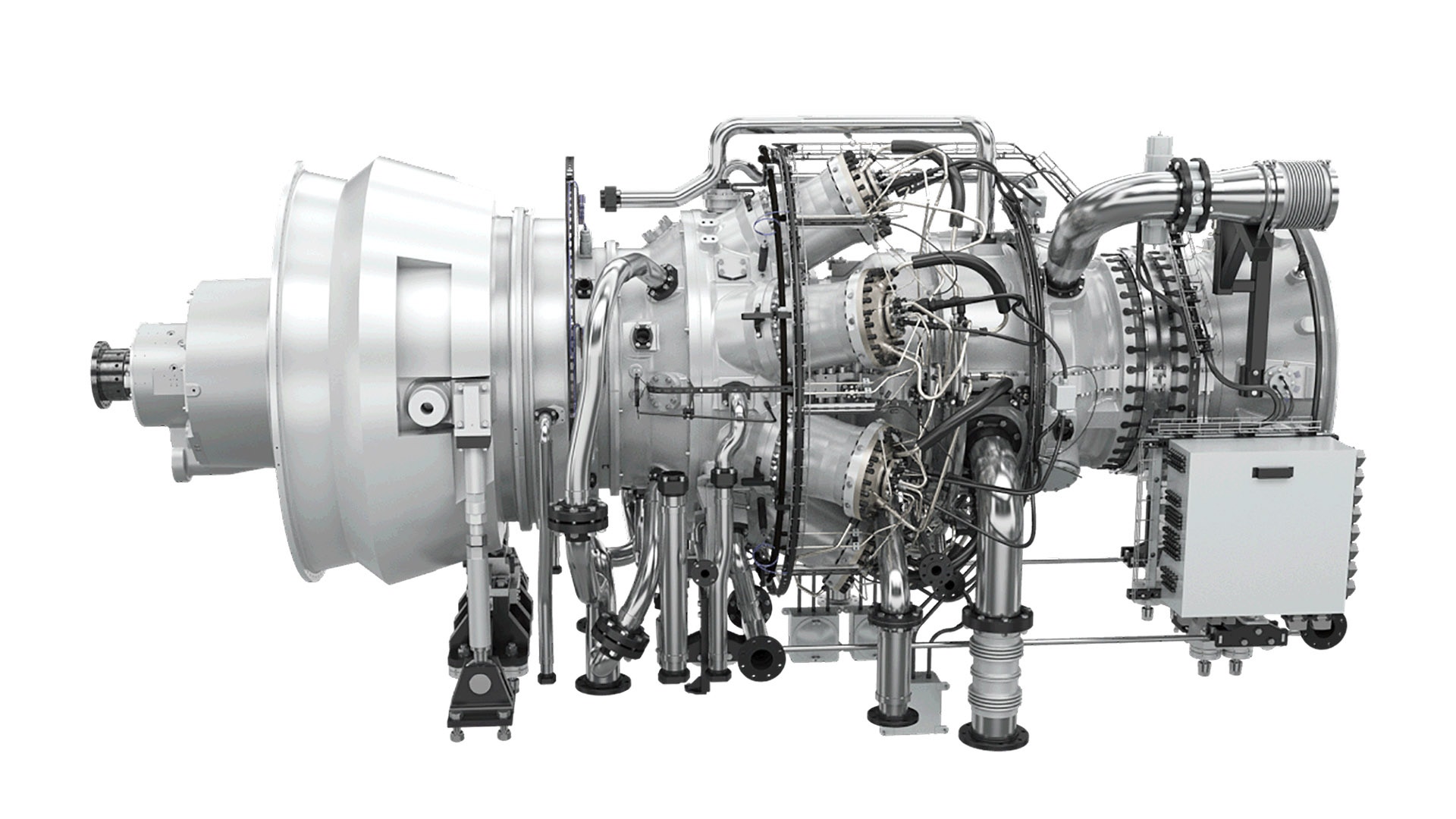

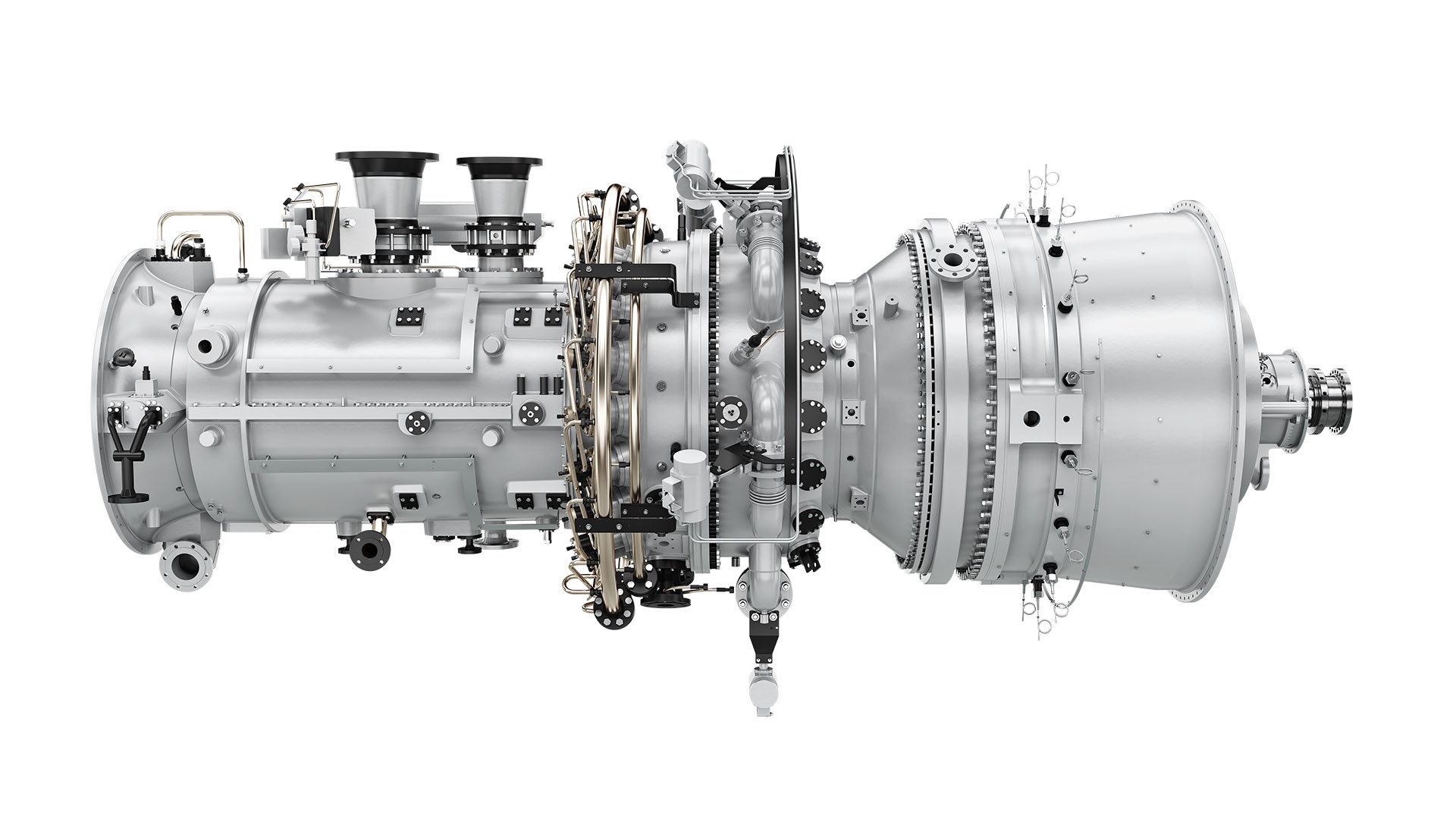

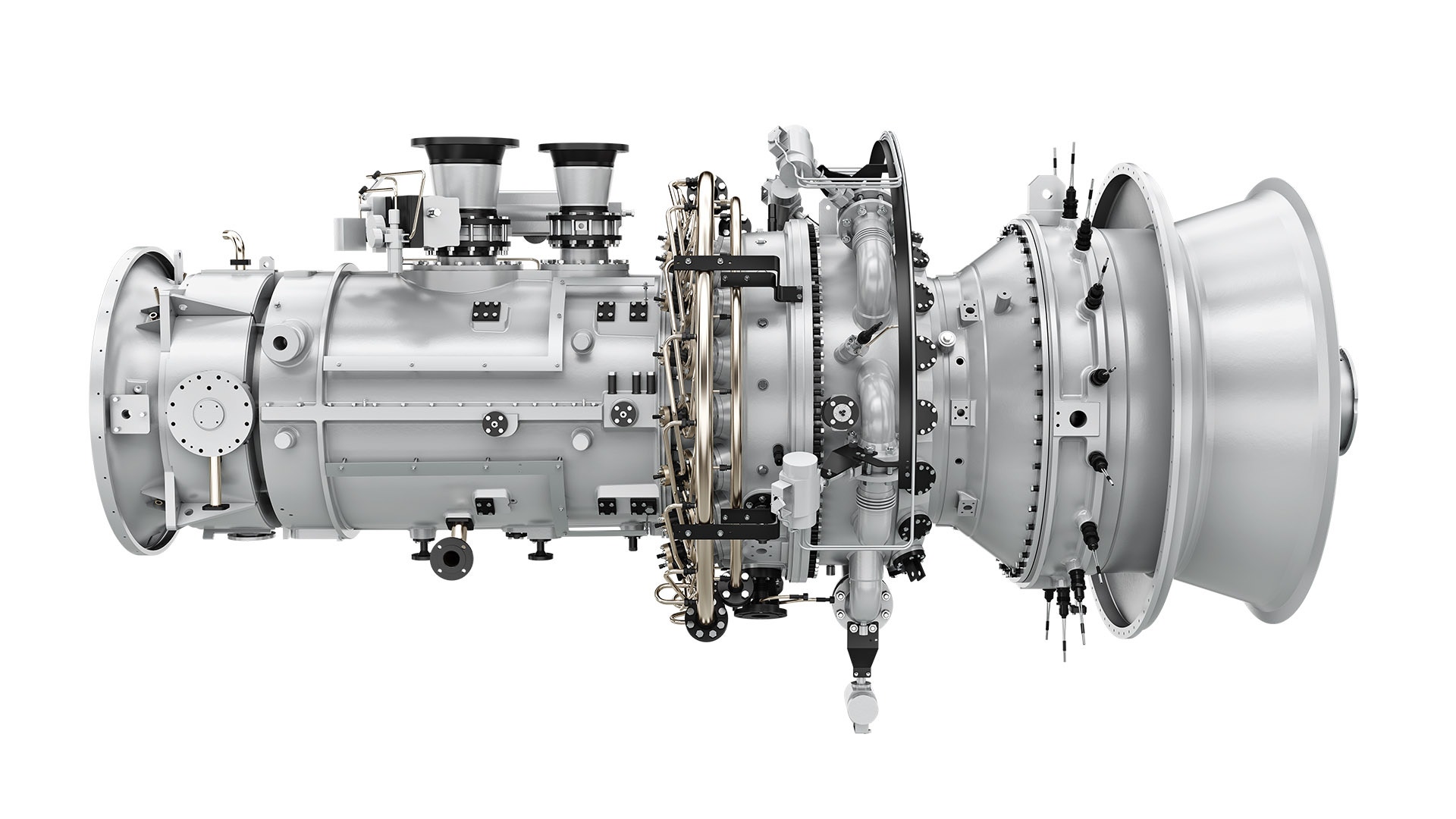

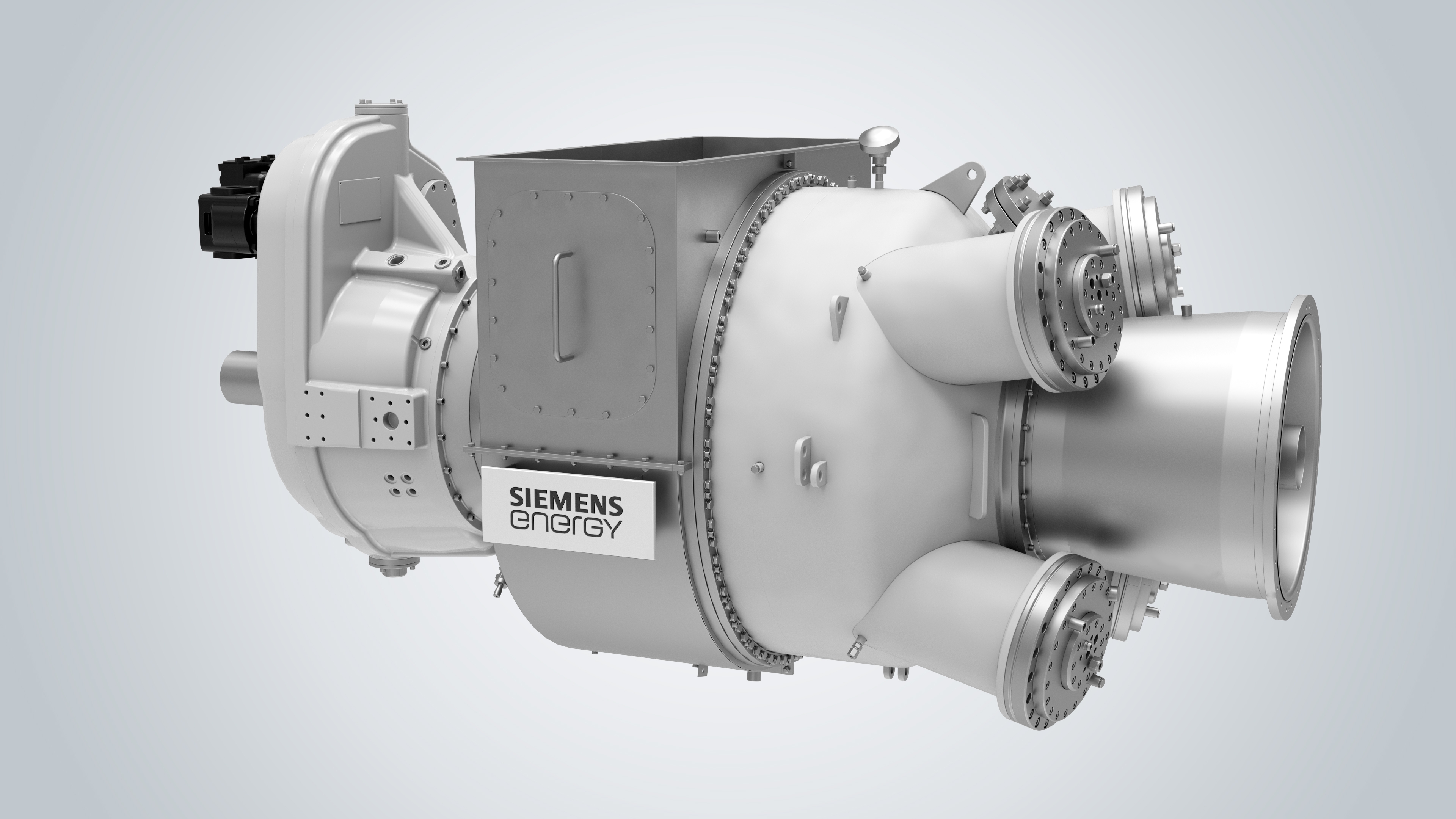

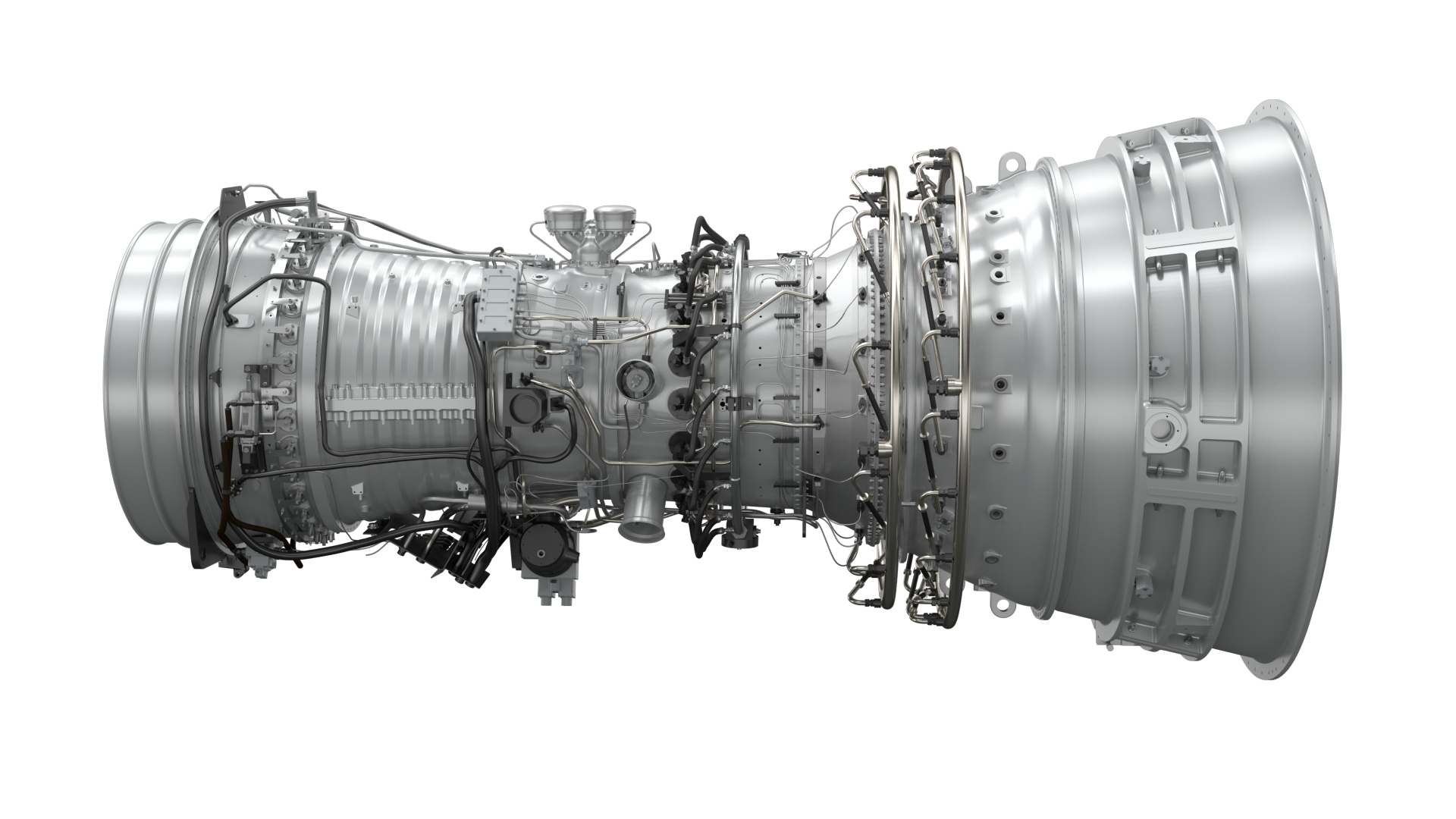

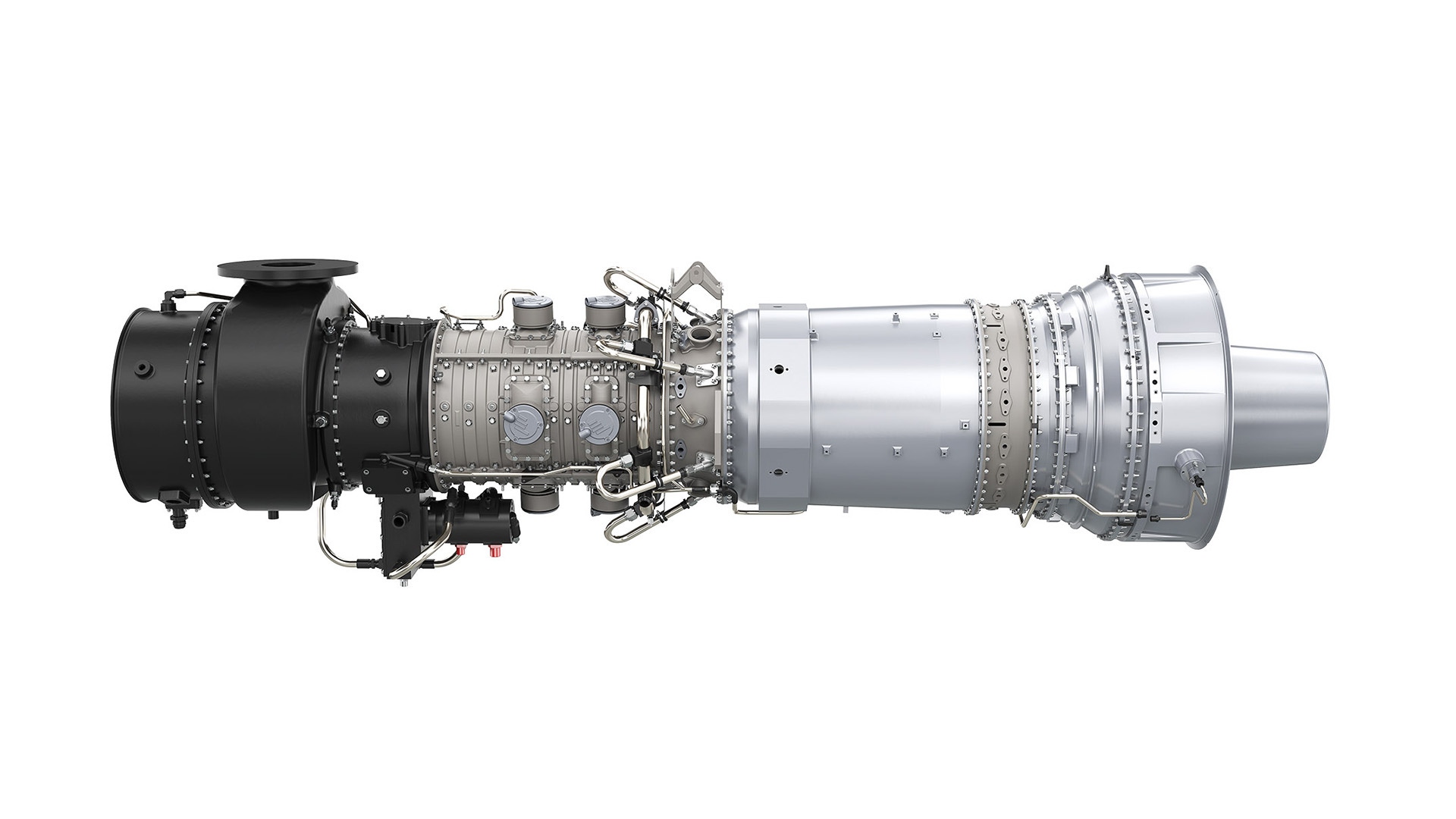

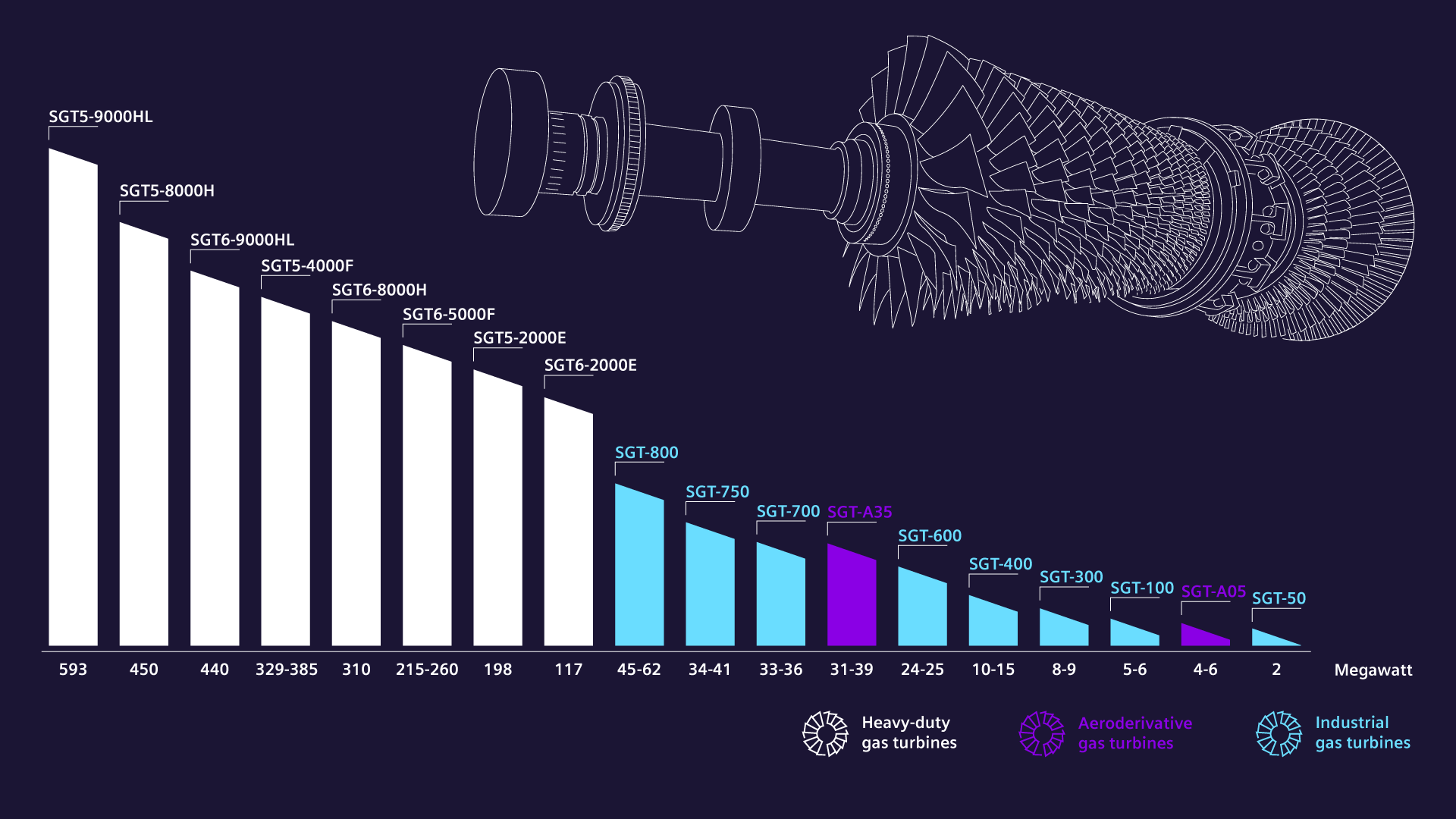

Aeroderivative, industrial and heavy-duty gas turbines up to 593 MWWhatever your business challenges may be, our gas turbines are precisely designed to master the dynamic energy market environment. By adhering to decarbonization processes and facilitating energy transition, we aim to contribute to a sustainable future.

Low lifecycle costs and an excellent return on investment right from the start are just two of the benefits that our gas turbine portfolio offers. Our gas turbines fulfill the high requirements of a wide spectrum of applications in terms of efficiency, reliability, flexibility, and environmental compatibility, all while supporting the shift to low-carbon energy sources.

Choose from our product range of heavy-duty, industrial and aeroderivative gas turbines, ranging up to 593 MW. Depending on your requirements, we provide you the right solution and scope for your market-specific needs. As a leading gas turbine manufacturer, we are committed to innovation and excellence in helping our customers navigate the energy transition.

Do you have a question regarding our products, solutions and services?

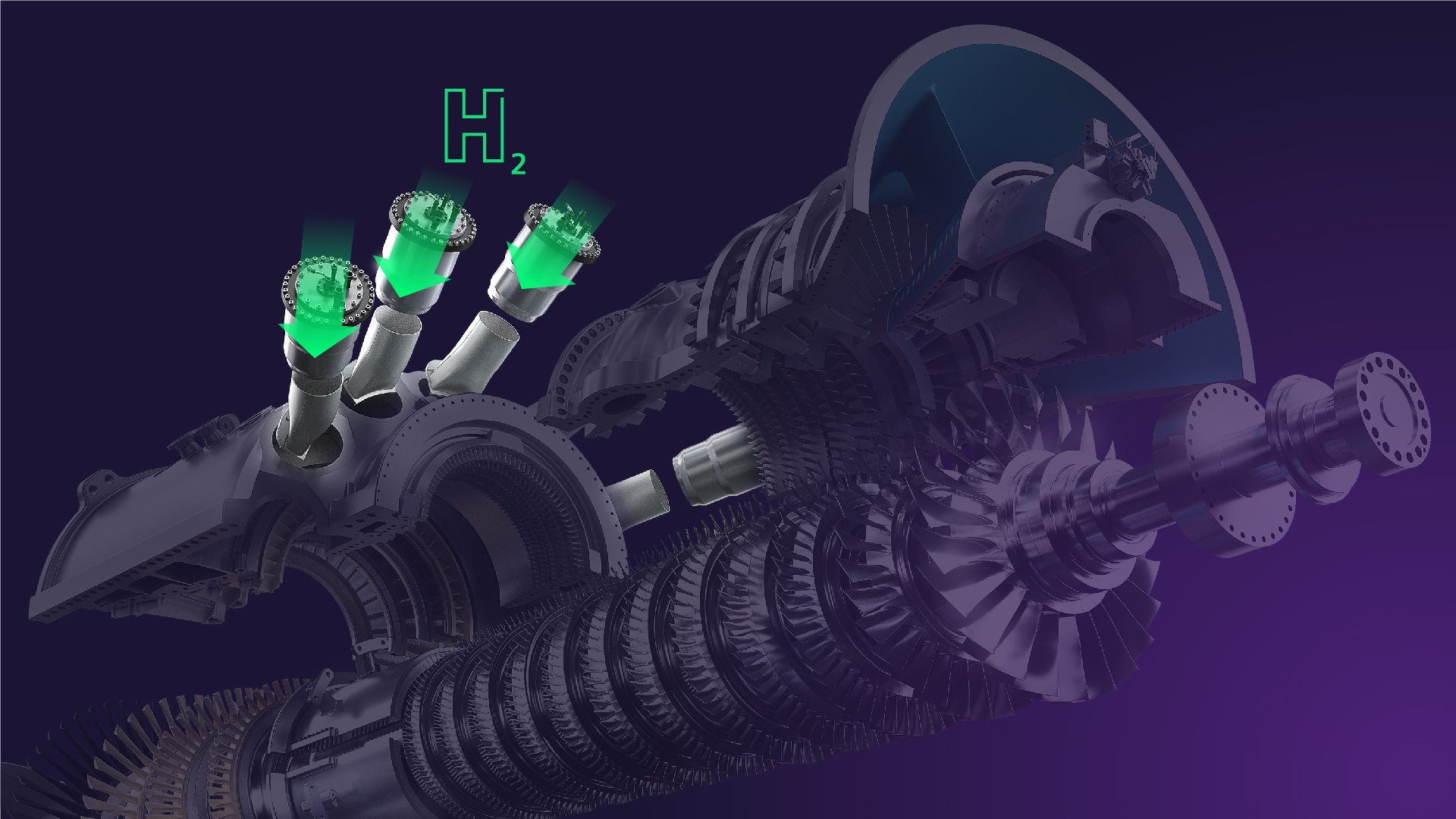

Hydrogen decarbonization calculator

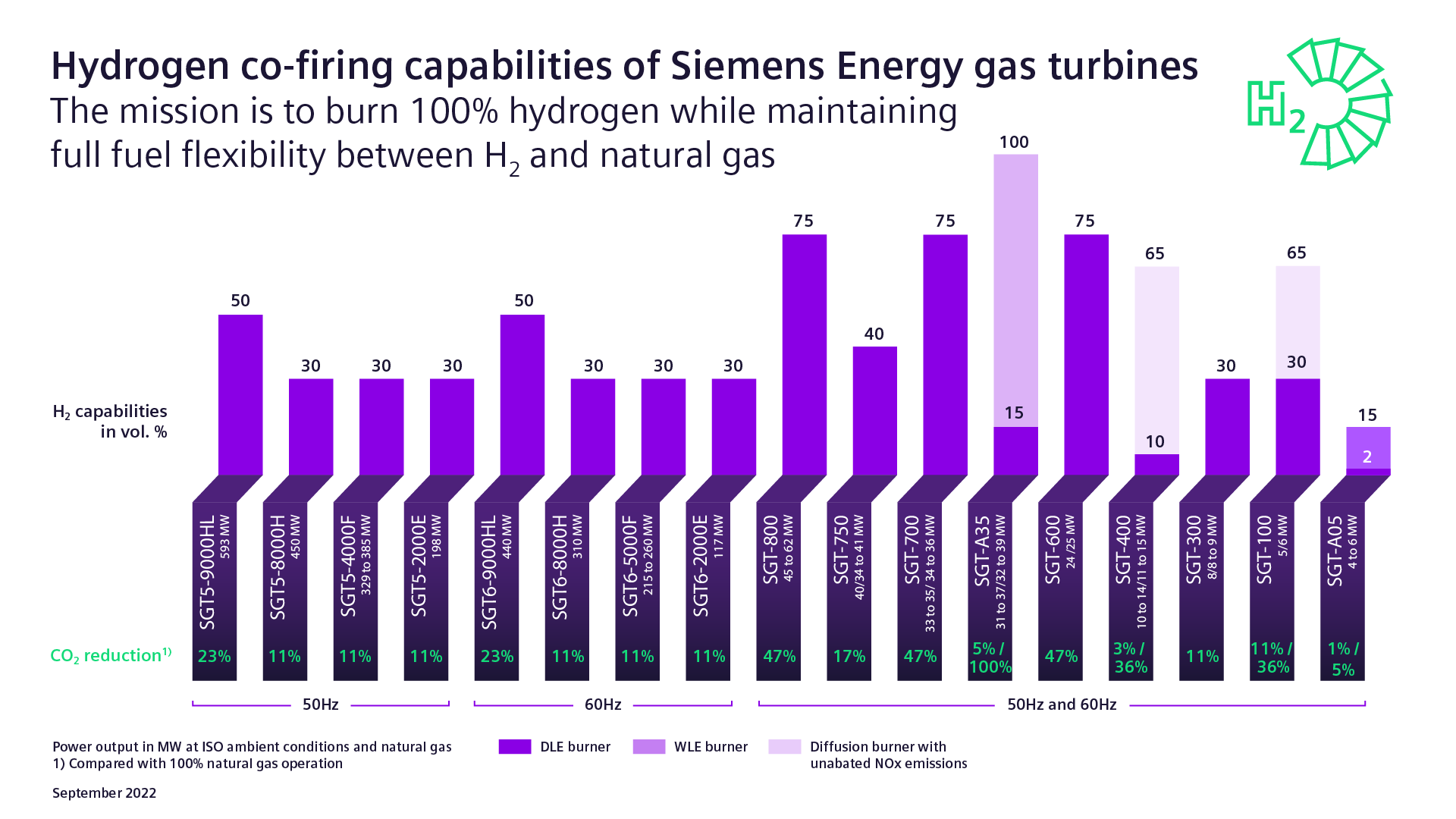

How can gas turbines help meeting the World Energy Council’s trilemma of secure, affordable and environmentally sustainable energy which turns into requirements on your business? How can you ensure the future role of existing assets as decarbonizations agents supporting the energy transition? Our new Whitepaper provides details on the vital role the ability of gas turbines to burn hydrogen as a fuel will play in a world trending towards full decarbonization and an unfolding hydrogen economy. We shed a light on the hydrogen combustion process, the capability and operational experience of our gas turbines on hydrogen combustion, upgrade options and our roadmap to 100% hydrogen capability.

Hydrogen readiness

New gas power plants being build today will very likely be converted at a later stage to burn a blend of hydrogen up to 100% during the lifetime of the plant. This means that provisions for cost efficient later retrofit to hydrogen are essential.

However, today’s new power plants will typically start operating with natural gas for several years. It is therefore crucial to build new natural gas fired power plants that can easily be upgraded and converted to hydrogen operations as hydrogen becomes available to the operator.

By doing so, natural gas fired power plants are future-proof and will be fit to meet the amount of hydrogen for which it has been made ready, with minimal conversion costs.

Do you have a question regarding our products, solutions and services?

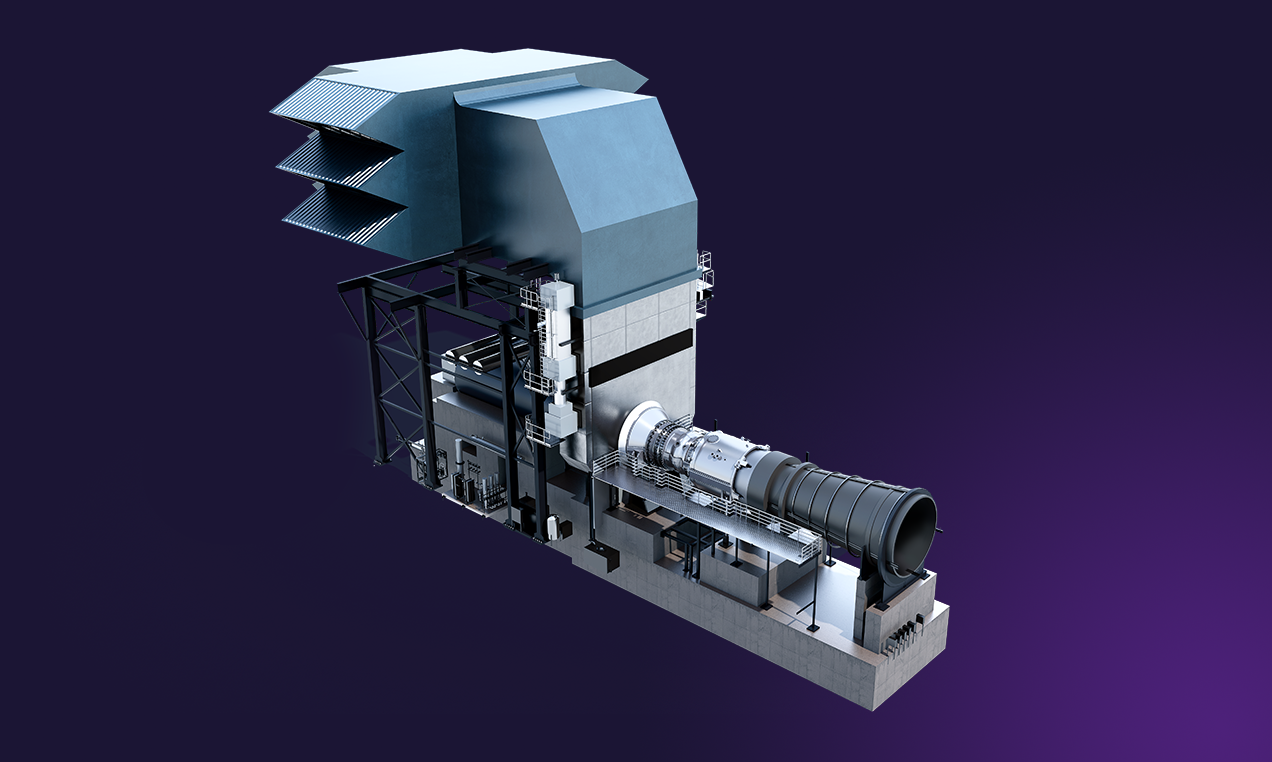

The scope you need - from package to full turnkey power plant

You can choose between different scopes of supply – from core turbine only, gas turbine packages up to complete gas-fired power plants.

Package

- GT and ST packages incl. auxiliaries

- GT air intake / exhaust system

- Fuel gas system

- Skids

- Connecting pipes

- GT and ST generators incl. auxiliaries

- Fire protection

- Electrical and I&C

- Options

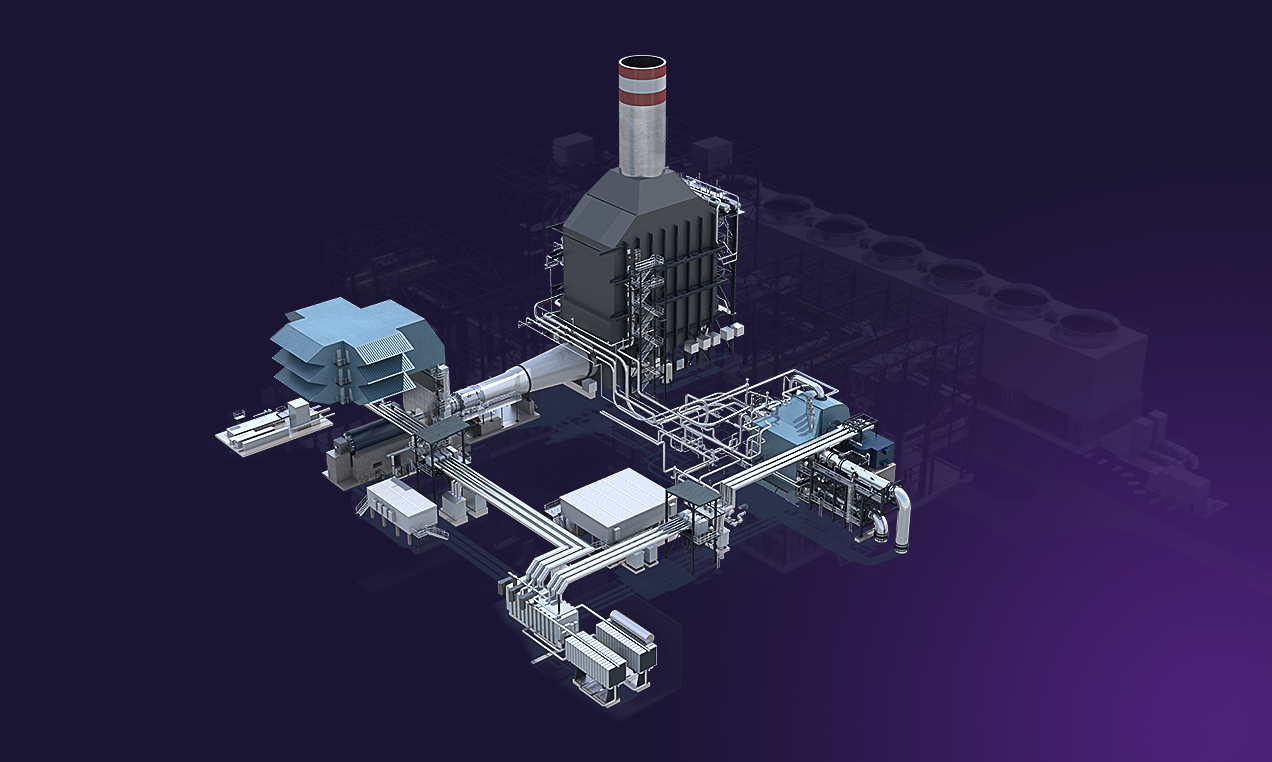

Power island

- HRSG

- Kettle boiler/rotor air cooler

- Condenser incl. air removal system

- Boiler feed pumps

- Condensate pumps

- Critical valves

- Fuel pre-heater with filter, metering station etc.

- Power island controls

- Options

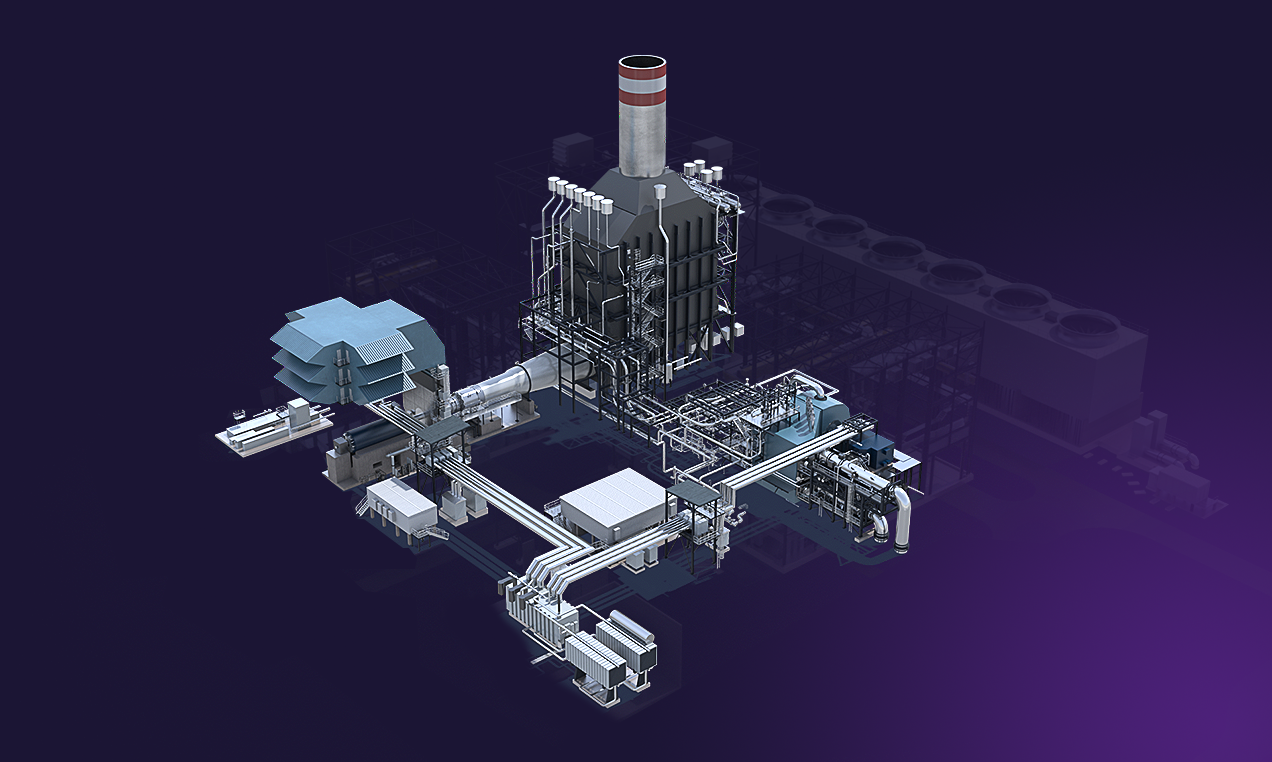

Power core

- W/S cycle, main piping, valves, HXs, etc. as prefab skids/pipe racks

- Circulating water pipe rack

- Closed cooling water system as prefab skid and pipe rack

- Relevant building layout engineering

- Options

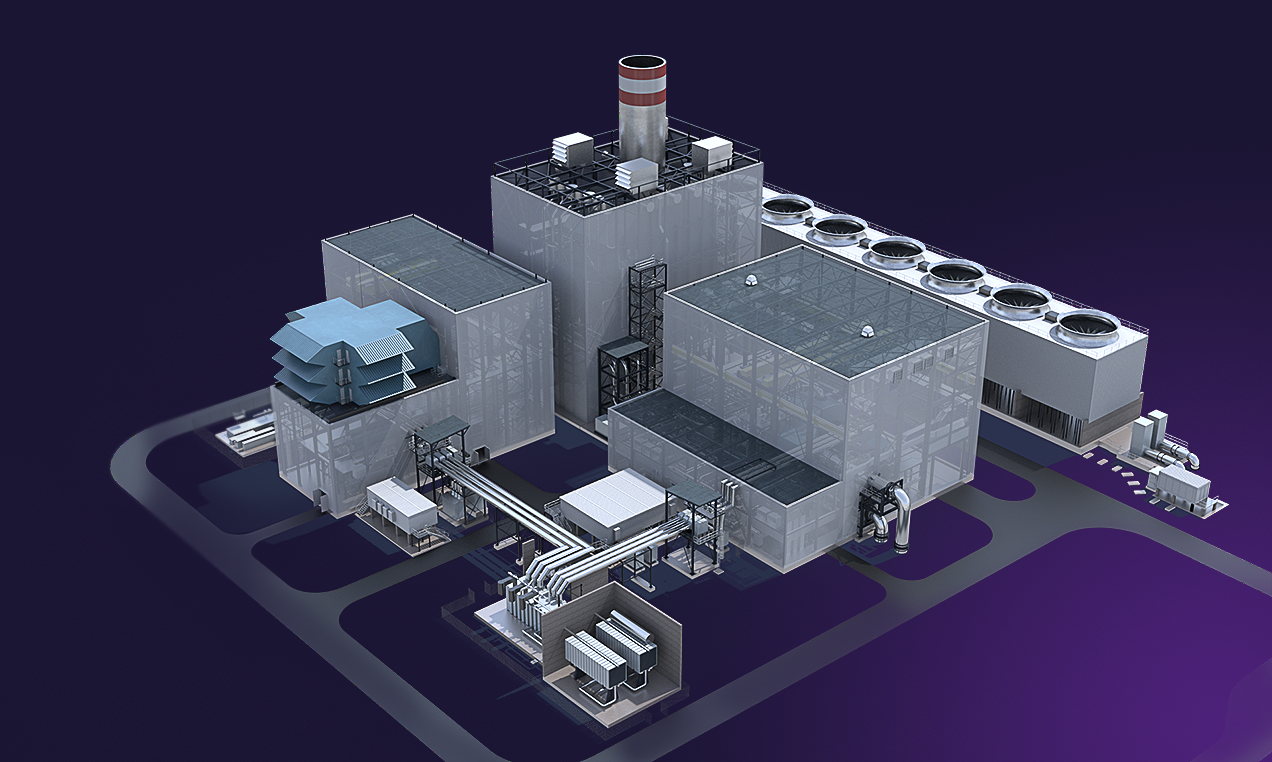

Turnkey power plant

- Plant cooling systems

- Water treatment

- Raw water system

- Waste water system/tanks

- Plant piping/valves

- Electrical equipment

- Plant control system

- Additional fire protection/fighting

- Erection/commissioning

- Buildings/structures

- Turbine hall ST or ST/ GT

- Cranes and HVAC

- Further options

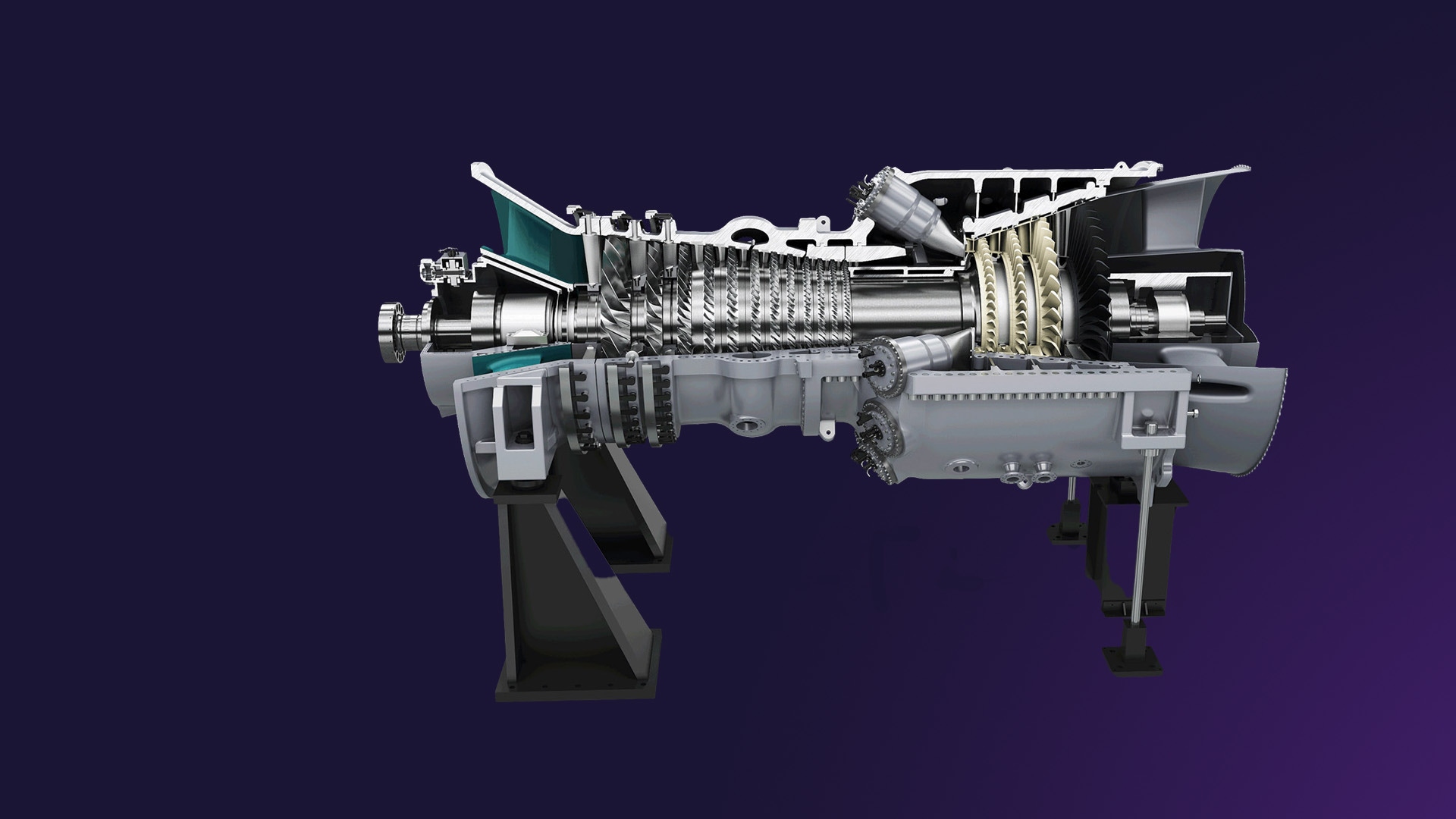

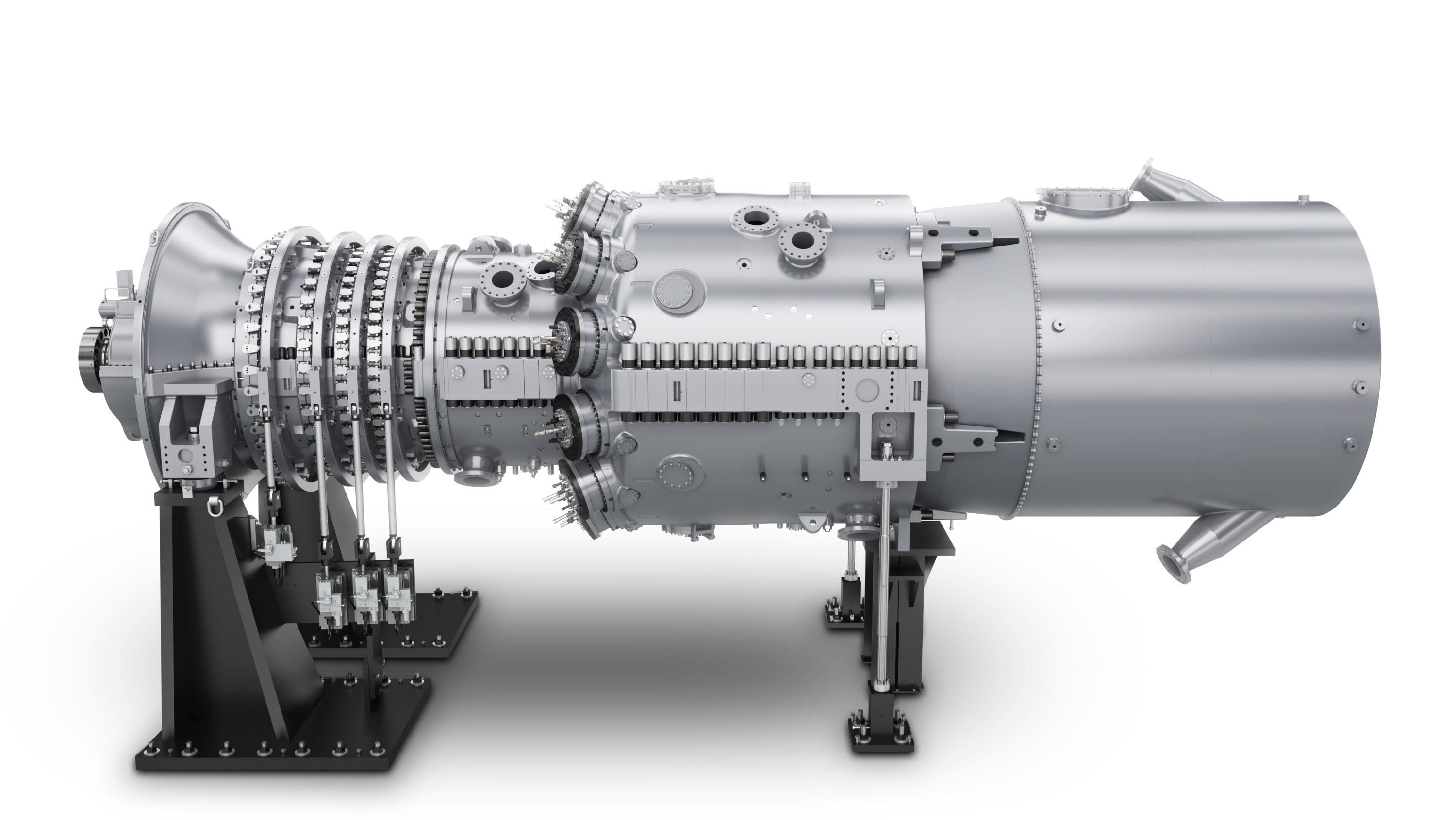

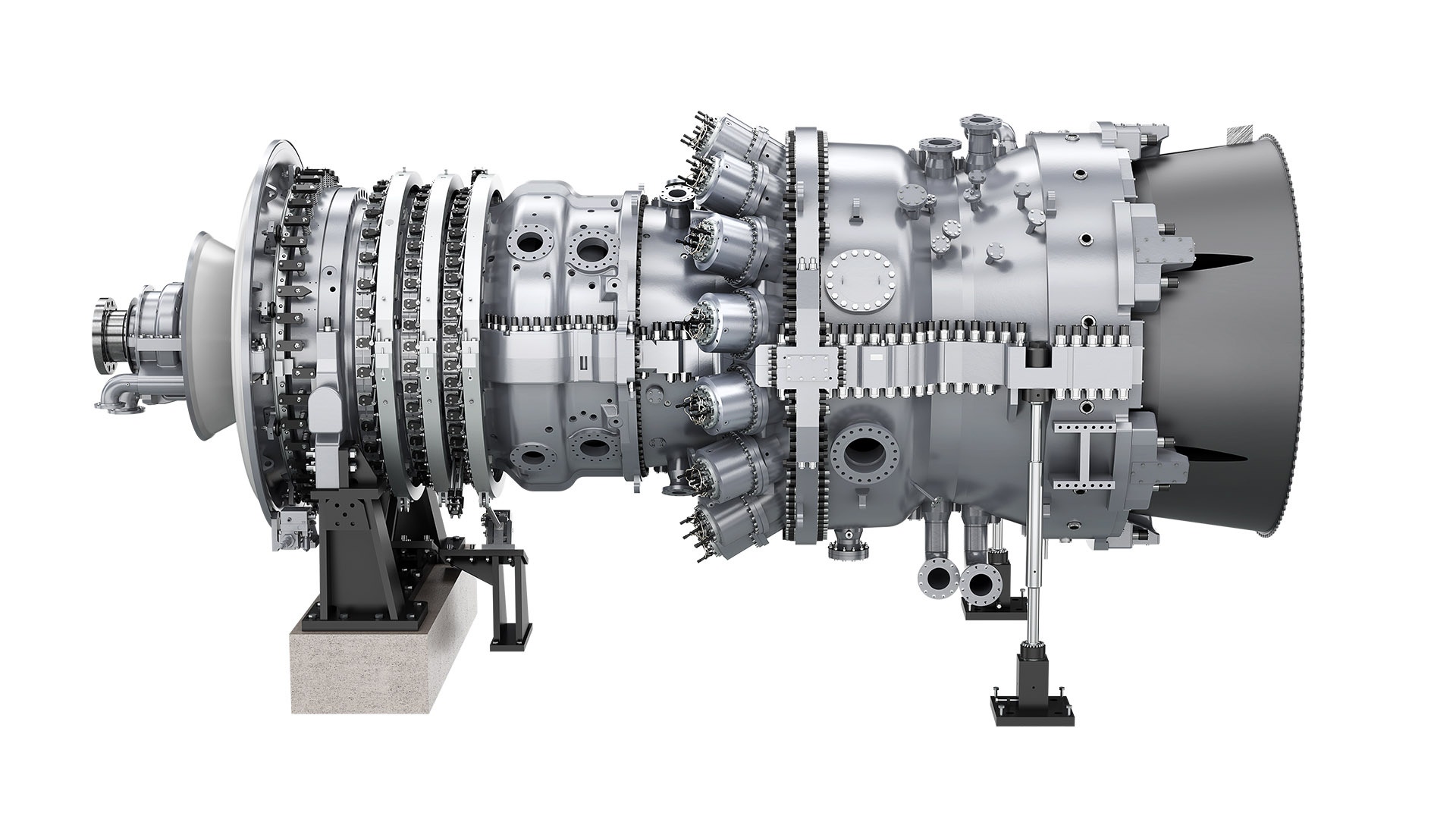

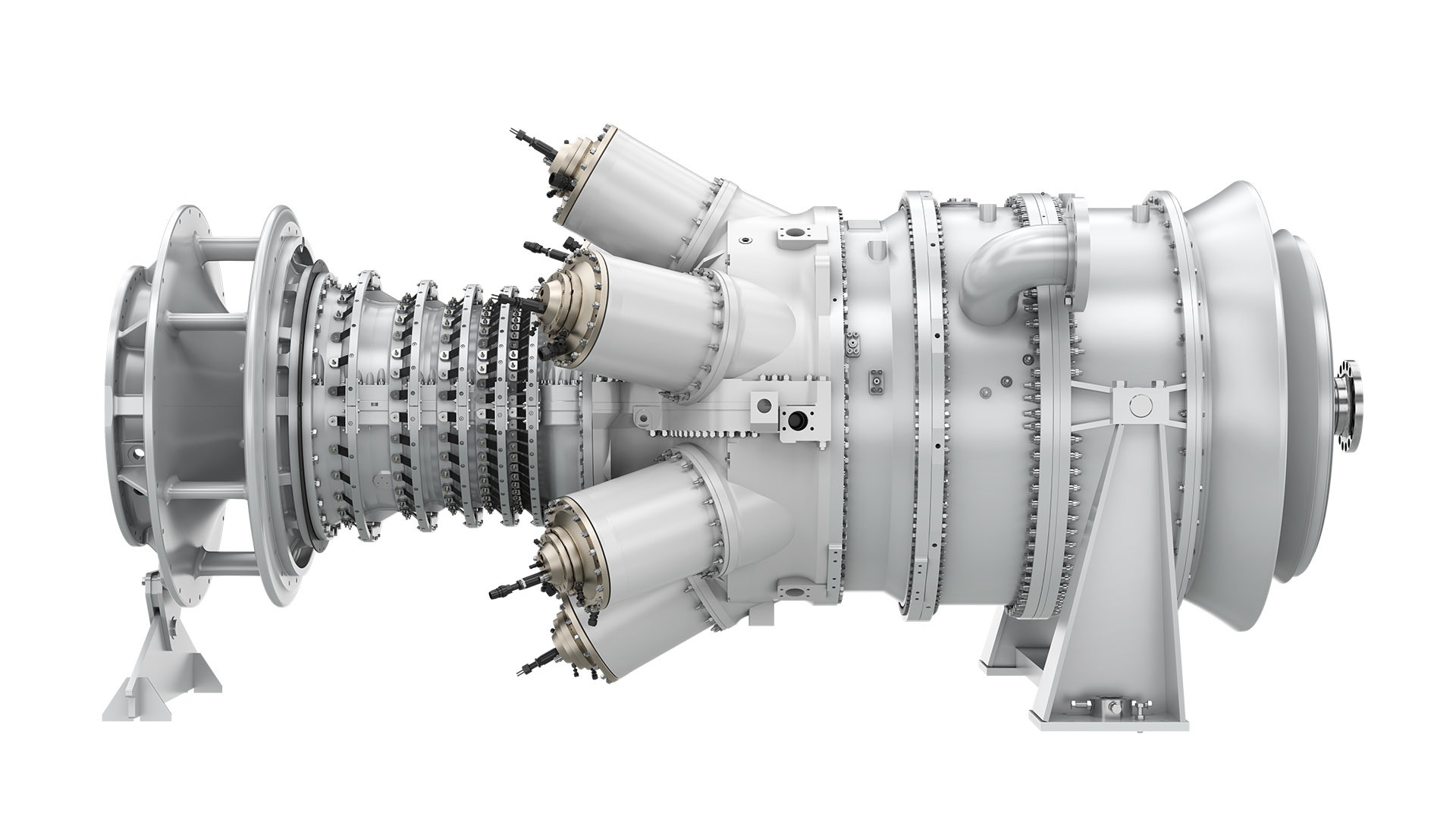

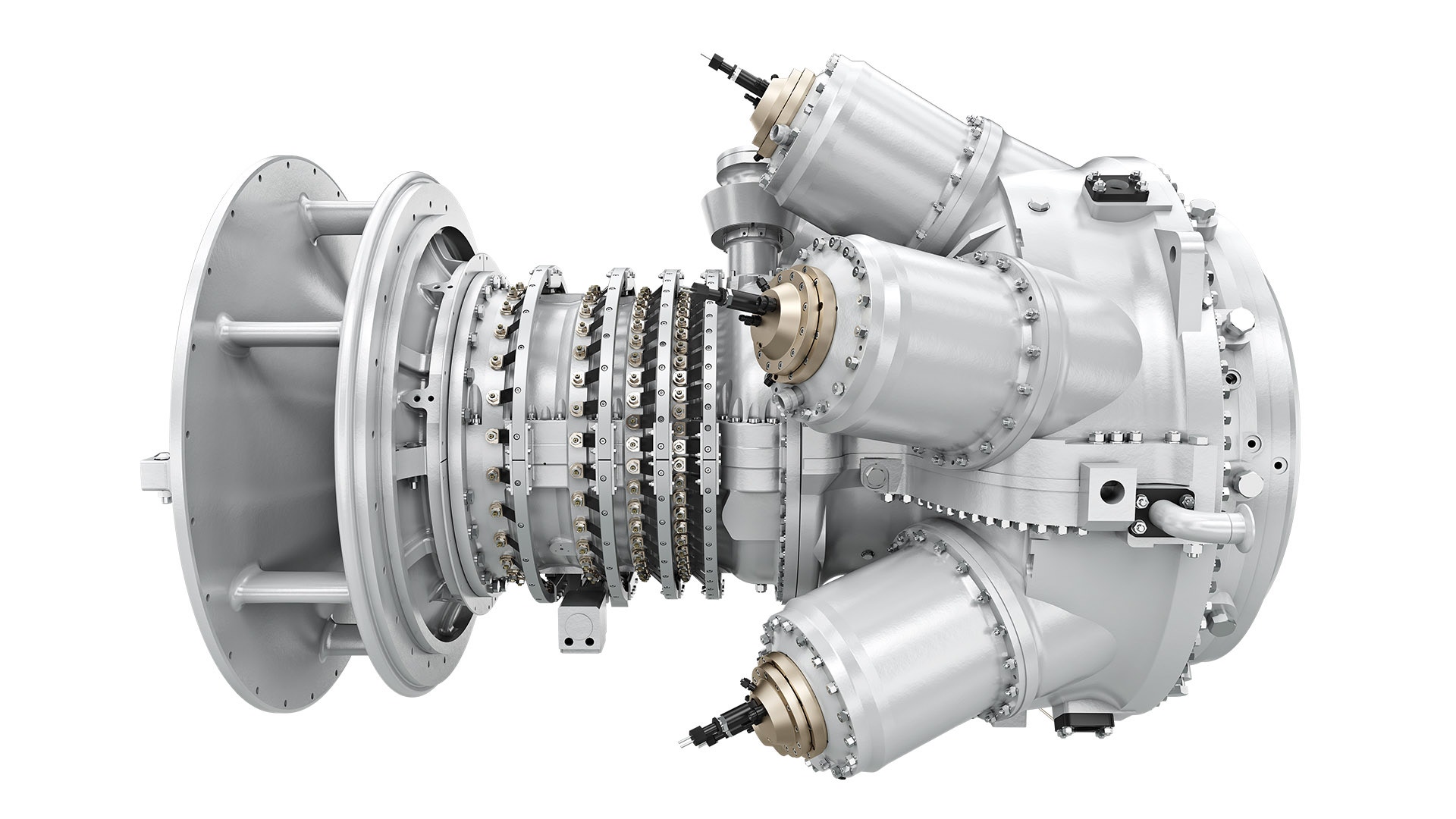

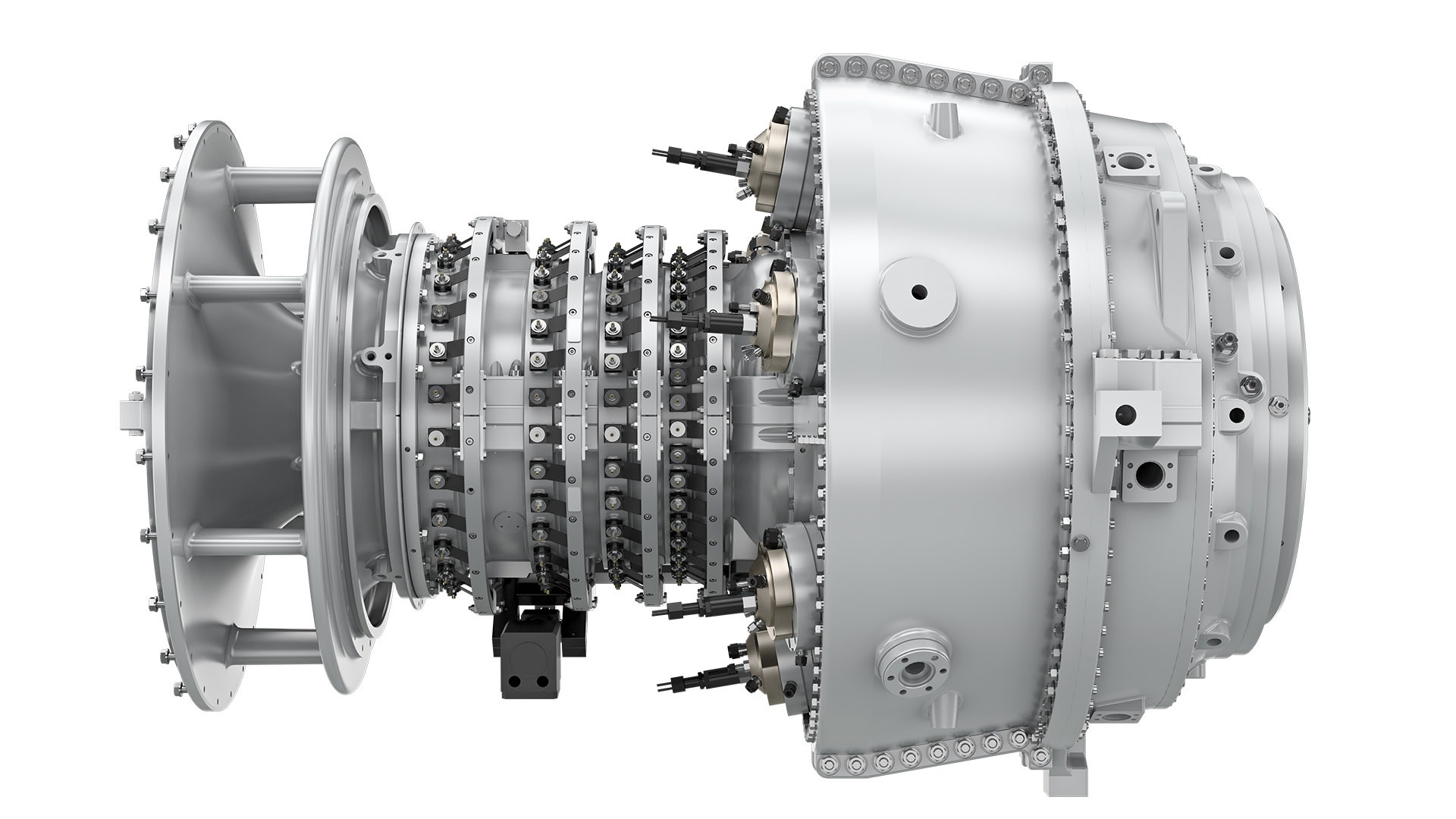

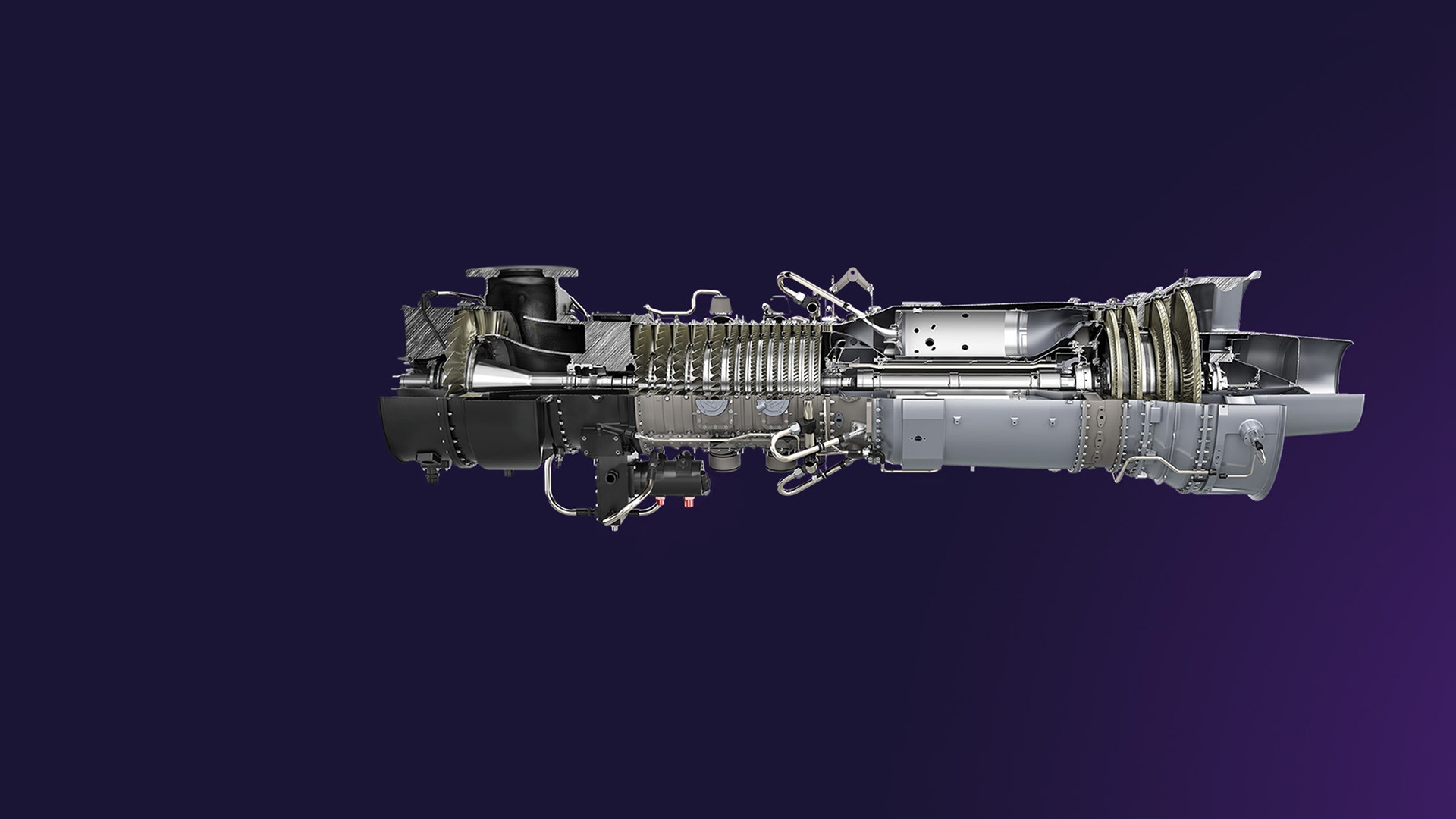

Gas turbine innovations for demanding markets

Driving innovation, developing new technologies, applying cutting-edge manufacturing technologies – that’s what we do to deliver the most advanced gas turbines that will set new standards in terms of efficiency, reliability and emission reduction. As innovation cycles are becoming shorter, the capability to test new designs and components becomes ever more important. In addition, new manufacturing technologies enable revolutionary designs and an unmatched, state-of-the-art spare part availability.

HL-class: Pushing power plant efficiency

Our HL-class gas turbines pave the way to the next level of efficiency. With a series of new but already tested technologies and design features we are driving technological upgrades throughout our entire fleet. The HL-class clears the way to efficiency levels beyond 64 percent.

We are setting the pace

Our gas turbines are a sustainable investment. They can run on hydrogen. By 2030, we want to increase the fuel-mix percentage of hydrogen to 100.

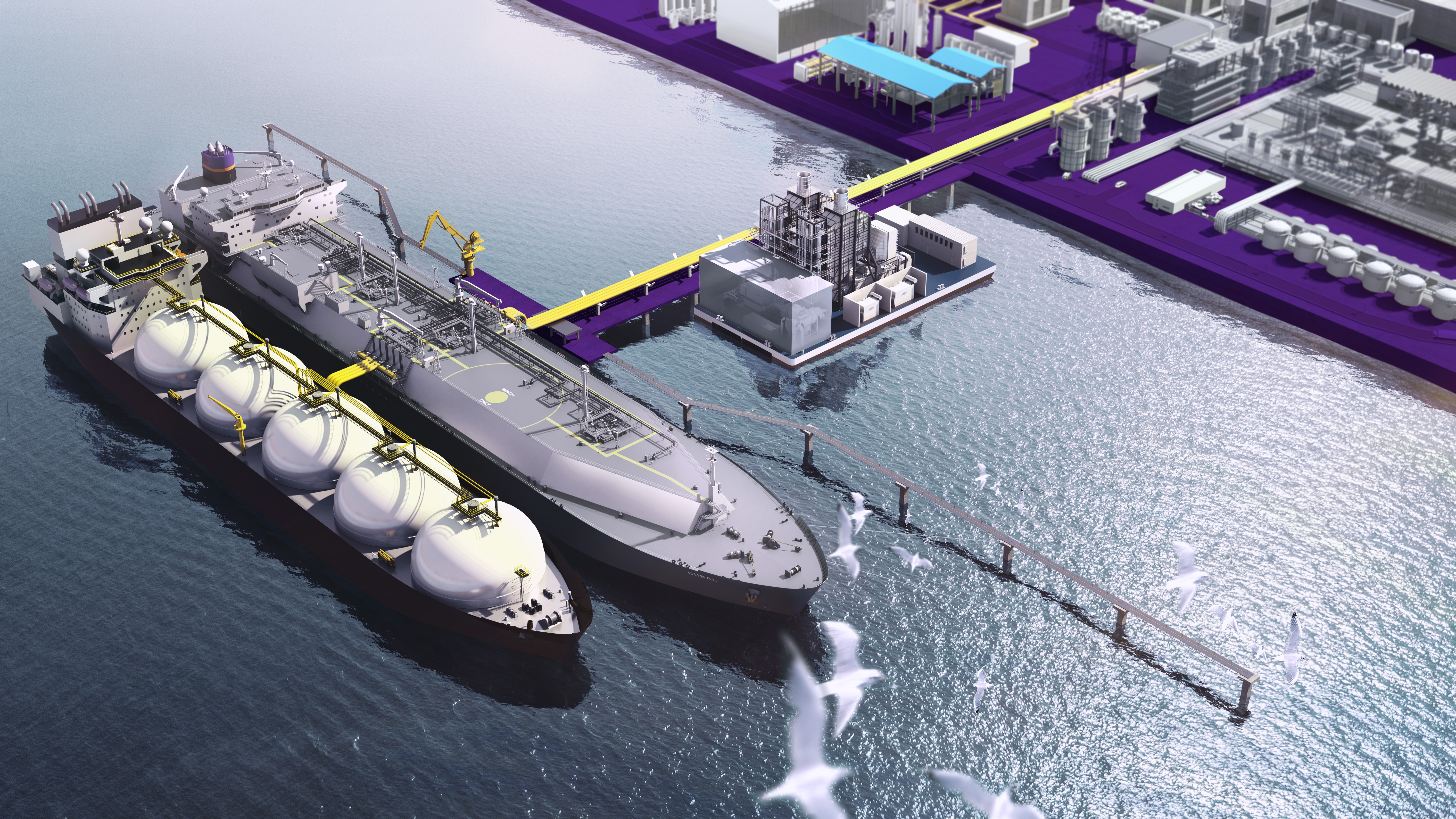

SeaFloat: Mobile floating power plants

With our highly efficient gas turbines on floating devices, a new class of mobile power plants becomes reality. The evolution of open and combined cycle power plants from land to sea is based on our successful gas turbines series SGT-800 and SGT-8000H.

Additive Manufacturing: Revolutionizing manufacturing and repair

Additive Manufacturing can speed up gas turbine repairs, prototyping and manufacturing of parts. Gas turbines can be designed faster, with increased flexibility, better materials, and optimized efficiency. This way, 3D printing enables cutting edge technologies with reduced time-to-market and quick upgrading of existing assets.

Turbine testing: Tested gas turbines you can count on

More than 7,000 Siemens Energy gas turbines are operating successfully all over the world. That’s because our gas turbines are thoroughly tested in our own test facilities to ensure they run smoothly even under the harshest conditions. Siemens Energy's gas turbine manufacturing plant and test centers boast the most modern and innovative test facilities in the world.

Turbine modernization: Improve your plant performance

We invest millions of euros in the development of new technologies to provide options to help you improve your operating plant performance. We develop enhancements to extend maintenance intervals, reduce emissions, provide operation flexibility, fuel flexibility options, and improve capability, reliability and availability. Profit from our ingenuity with comprehensive modernization and upgrade options for gas turbines.

Find out more about our gas turbine offerings

In our download section, you can find brochures, technical papers and more, or can contact us directly for specific inquiries.

Brochures

Gas turbine portfolio (interactive PDF)

Hydrogen power plants service and solutions

Technical papers and press releases

References

Siemens Energy gas turbines are operating in more than 60 countries. We provide proven technology with more than 7000 installed heavy-duty, industrial and aeroderivative gas turbines.

Do you have a question regarding our products, solutions and services?