Innovative power plant solutions

Individual power plants that create value

As energy consumption will continue to increase in the years to come, efficient power generation will be a vital component to reliable, eco-friendly energy systems. Fluctuations are more frequently and at shorter intervals. Energy markets around the world are demanding more and more from their participants – whether that be responding flexibly to fluctuations, observing increasingly stringent emission limits, supplying power at lower and lower costs, or ensuring supply under adverse conditions. Anyone looking to stay ahead of the game needs more than an “off-the-shelf” power plant. You need an individual power plant solution aligned with your objectives? Whether it’s a small, integrated system or a heavy-duty power plant, a purely gas-fired simple cycle or a hydrogen or a combined cycle power plant, we’ll collaborate closely with you to find and construct a solution optimized specifically for you.

Power plant components

Power of innovation built on tradition

Our ideas grow from experience: In 1866, Werner von Siemens developed the first electric generator, and Siemens Energy built the first power plant in 1885. This spirit of invention is what has driven our power business ever since. Since 1990, we`ve brought more than a hundred turnkey power plants online, supplying hundreds of GW of electricity. Each of them has been constructed with customized solutions to meet our customers’ individual challenges. In other words, we’ve always been involved in supplying electricity to industries, regions, and people all over the world. That’s our purpose. Let’s make tomorrow different today!

Sustainability for your power plant project: EHS measures minimize the risks

Health and safety are our top priority – for our own employees and those of our suppliers and partners. That’s why we work with management plans and assessments, and that’s why we train and test everyone involved. We regularly visit sites and evaluate the commitment of each individual participant, whether they’re in the office or at the construction site – with one clear goal: to keep people safe from harm. Our EHS (environment, health, and safety) measures significantly cut accident rates and downtime. And in the end, they pay off for your project: with a positive transfer of knowledge to your local team, faster completion, reduced non-conformance-costs (NCCs), and a good reputation.

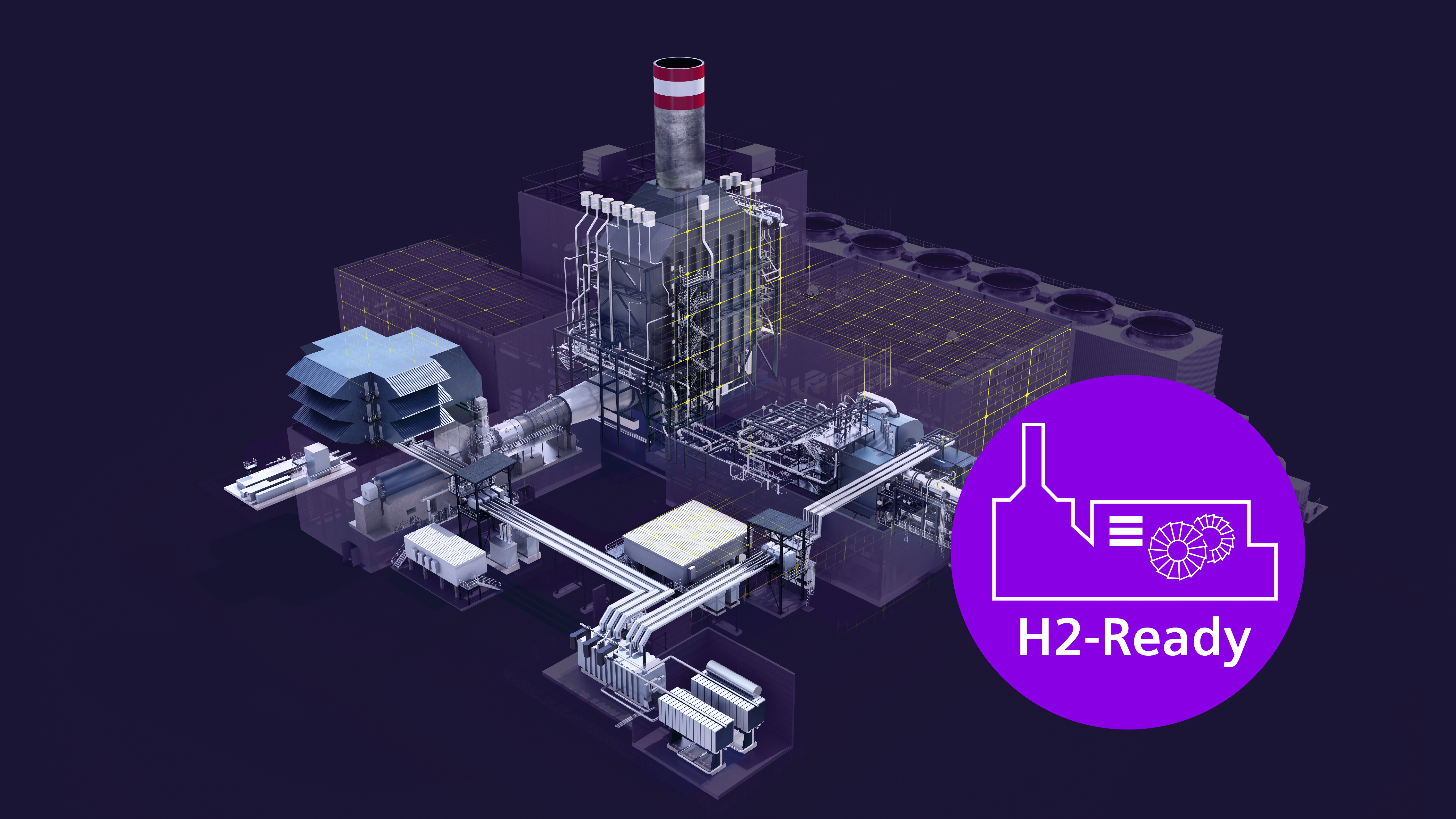

Lowering CO₂ by using hydrogen for power generation

New gas power plants being build today will very likely be converted at a later stage to burn a blend of hydrogen up to 100% during the lifetime of the plant. This means that provisions for cost efficient later retrofit to hydrogen are essential. Hydrogen ready should not be confused with hydrogen capability. However, today’s new power plants will typically start operating with natural gas for several years.

It is therefore crucial to build new natural gas fired power plants that can easily be upgraded and converted to hydrogen operations as hydrogen becomes available to the operator. By doing so, natural gas fired power plants are future-proof and will be fit to meet the amount of hydrogen for which it has been made ready, with minimal conversion costs.

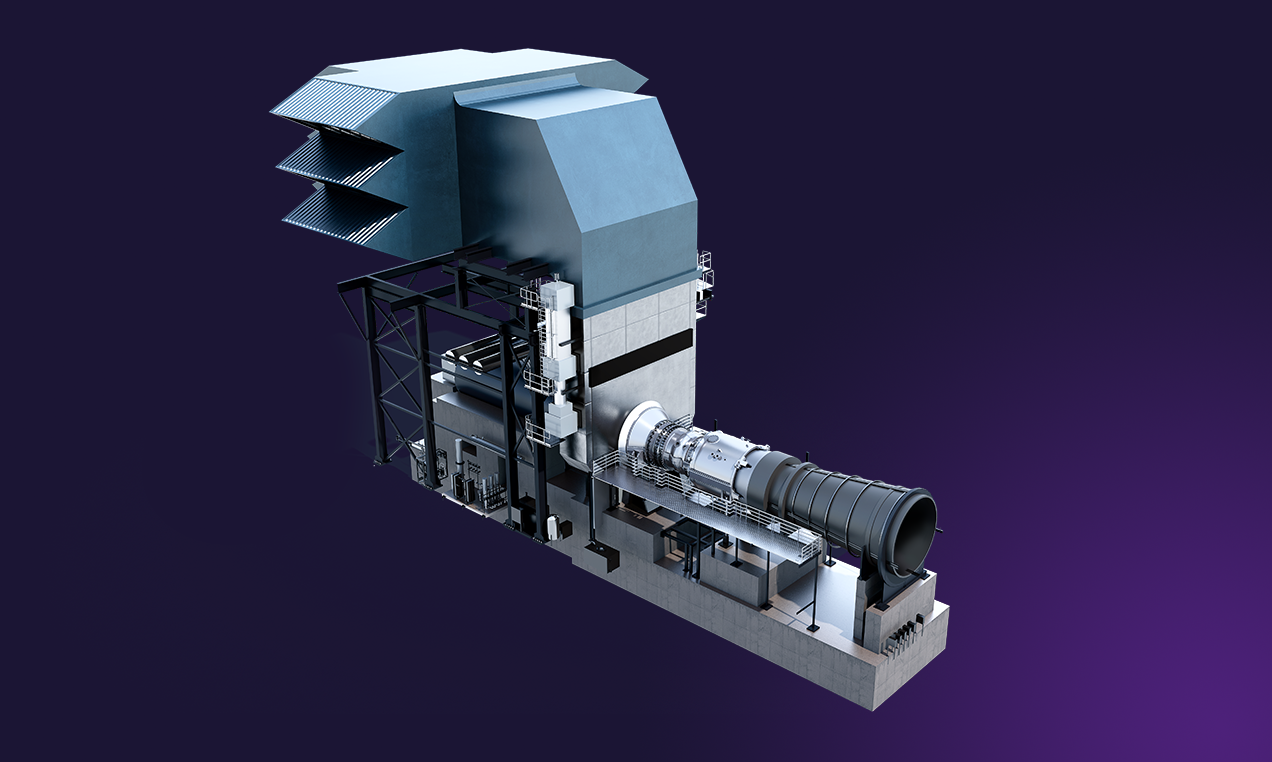

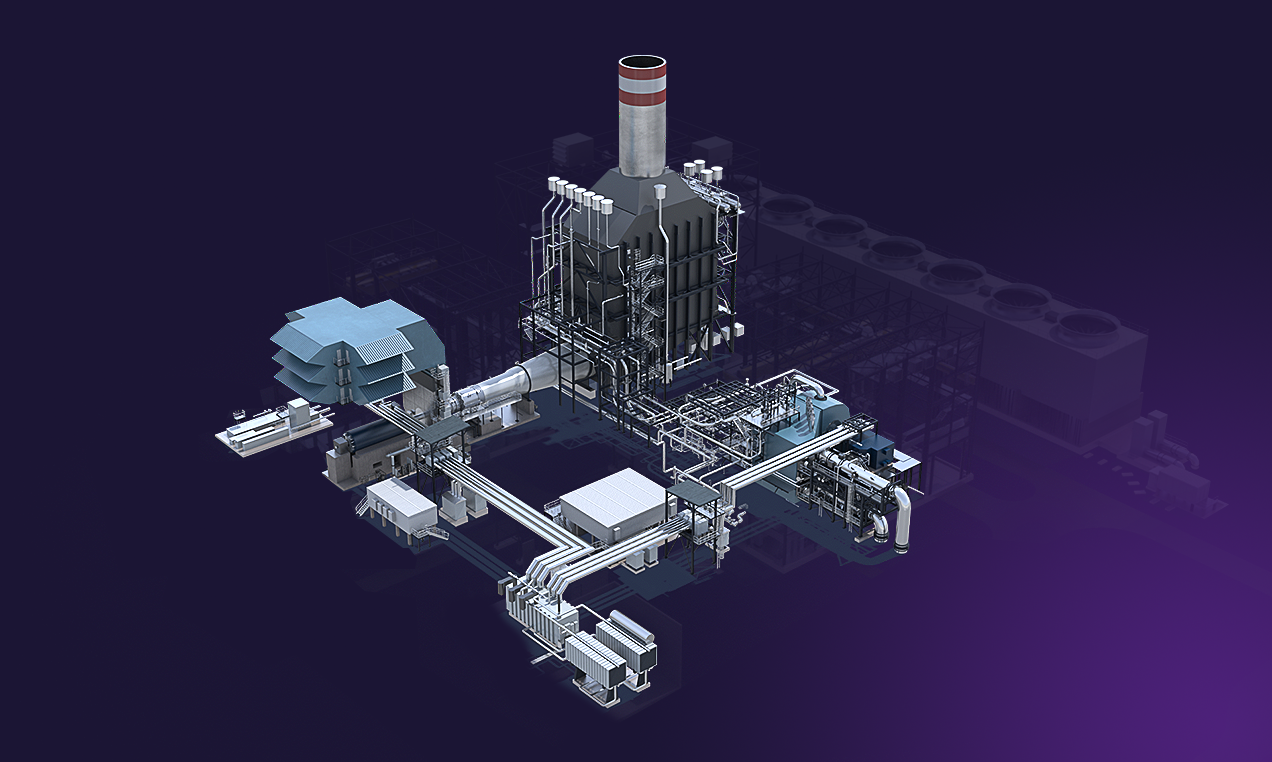

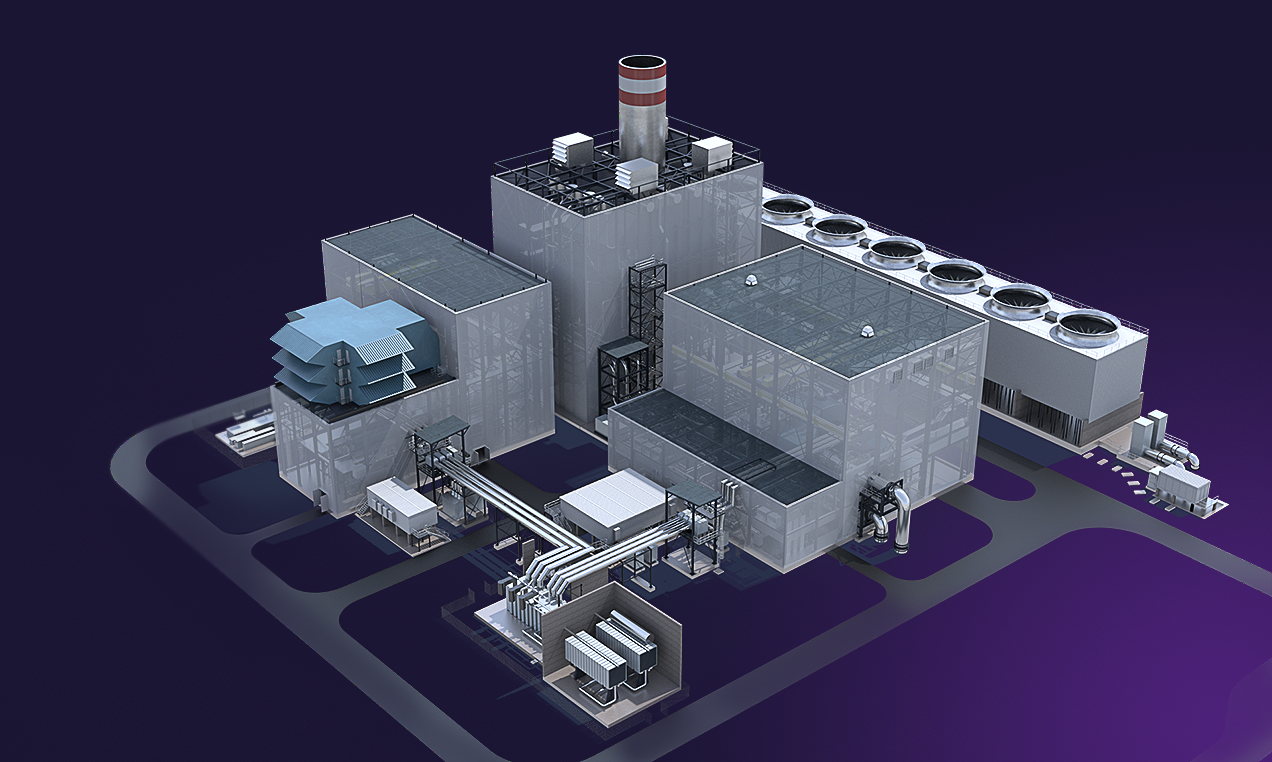

The scope you need - From package to full turnkey power plant

You can choose between different scopes of supply – from core turbine only, gas turbine packages up to complete gas-fired power plants.

Package

- GT and ST packages incl. auxiliaries

- GT air intake / exhaust system

- Fuel gas system

- Skids

- Connecting pipes

- GT and ST generators incl. auxiliaries

- Fire protection

- Electrical and I&C

- Options

Power island

- HRSG

- Kettle boiler/rotor air cooler

- Condenser incl. air removal system

- Boiler feed pumps

- Condensate pumps

- Critical valves

- Fuel pre-heater with filter, metering station etc.

- Power island controls

- Options

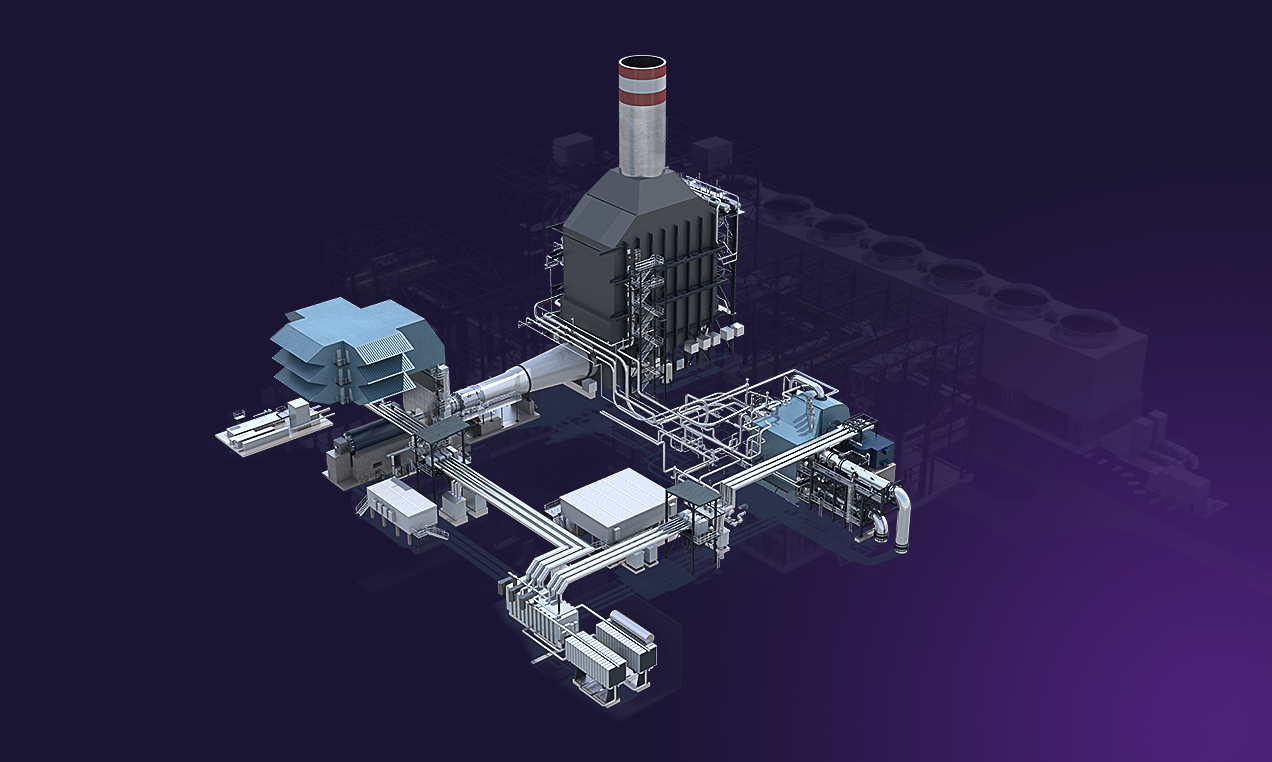

Power core

- W/S cycle, main piping, valves, HXs, etc. as prefab skids/pipe racks

- Circulating water pipe rack

- Closed cooling water system as prefab skid and pipe rack

- Relevant building layout engineering

- Options

Turnkey power plant

- Plant cooling systems

- Water treatment

- Raw water system

- Waste water system/tanks

Our power plants supply the world: examples of successful partnerships

More than 1,500 Siemens Energy power plants are in operation around the world. Here is a selection of the top projects we’ve implemented for our customers.

Are you looking for a power plant that’s especially efficient or extraordinarily flexible? One that will stabilize your power supply? Or one that will provide your industrial facility with power at a reasonable cost? Whatever you might need: We work alongside you to find the perfect solution for the tasks you face.