Robotic technology inspections

Siemens Energy partners with Gecko Robotics to provide advanced technology solutions to increase the efficiency and safety of facility operations, prevent downtime, and promote energy efficiency and security. Our connected solutions combine wall-climbing inspection robots and an AI-powered data platform to provide clients with a unique window into the current and future health of their physical assets.

Harness the power of robotics to bring about a safer, more efficient working environment

Westlake highlight why robotic inspections are the way forward. Significantly reducing safety hazards, and collecting and analyzing an abundance of data on equipment integrity, these inspections can result in substantial efficiency and process improvements.

Improve safety risks, health, and reduce environmental hazards with robotic inspections

To provide customers with safe and proficient technology, Siemens Energy now monitors and inspects plant machinery while minimizing the exposure to hazardous work environments.

- Eliminate risk associated with confined space entry

- Reduce working at height risk

- Reduced need for rope access inspections

- Faster inspections

- Early detection of equipment malfunction and leaks

Download EHS impact flyer

Siemens Energy and Gecko Robotics drive safer inspections

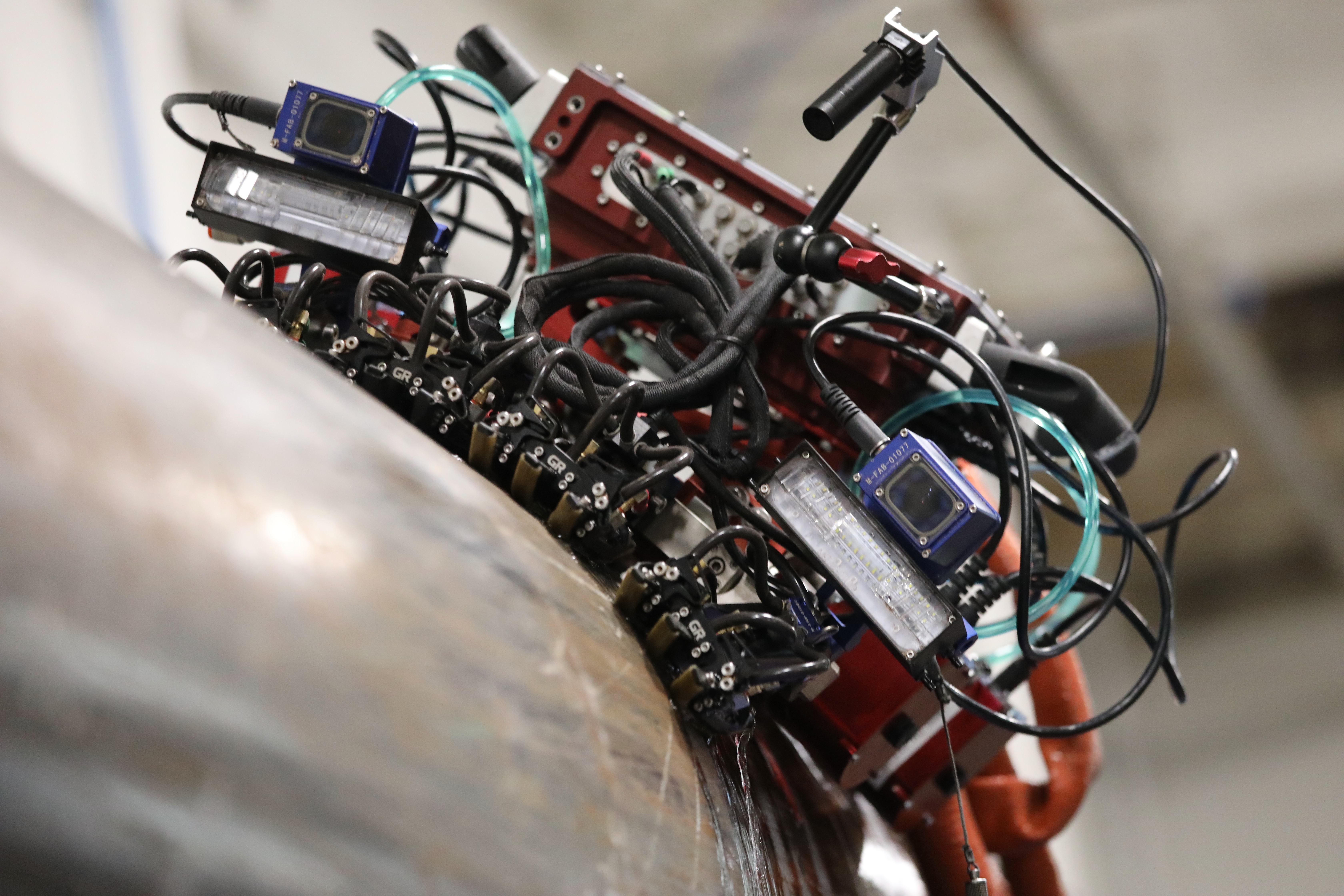

We completed a boiler tube inspection at ENGIE Rodenhuize's biomass power plant in Belgium. Using cutting-edge inspection technology developed by Gecko Robotics, we successfully gathered valuable data for efficient asset management decisions.

Download NDT Flyer

State of the art robotic solutions for multiple applications

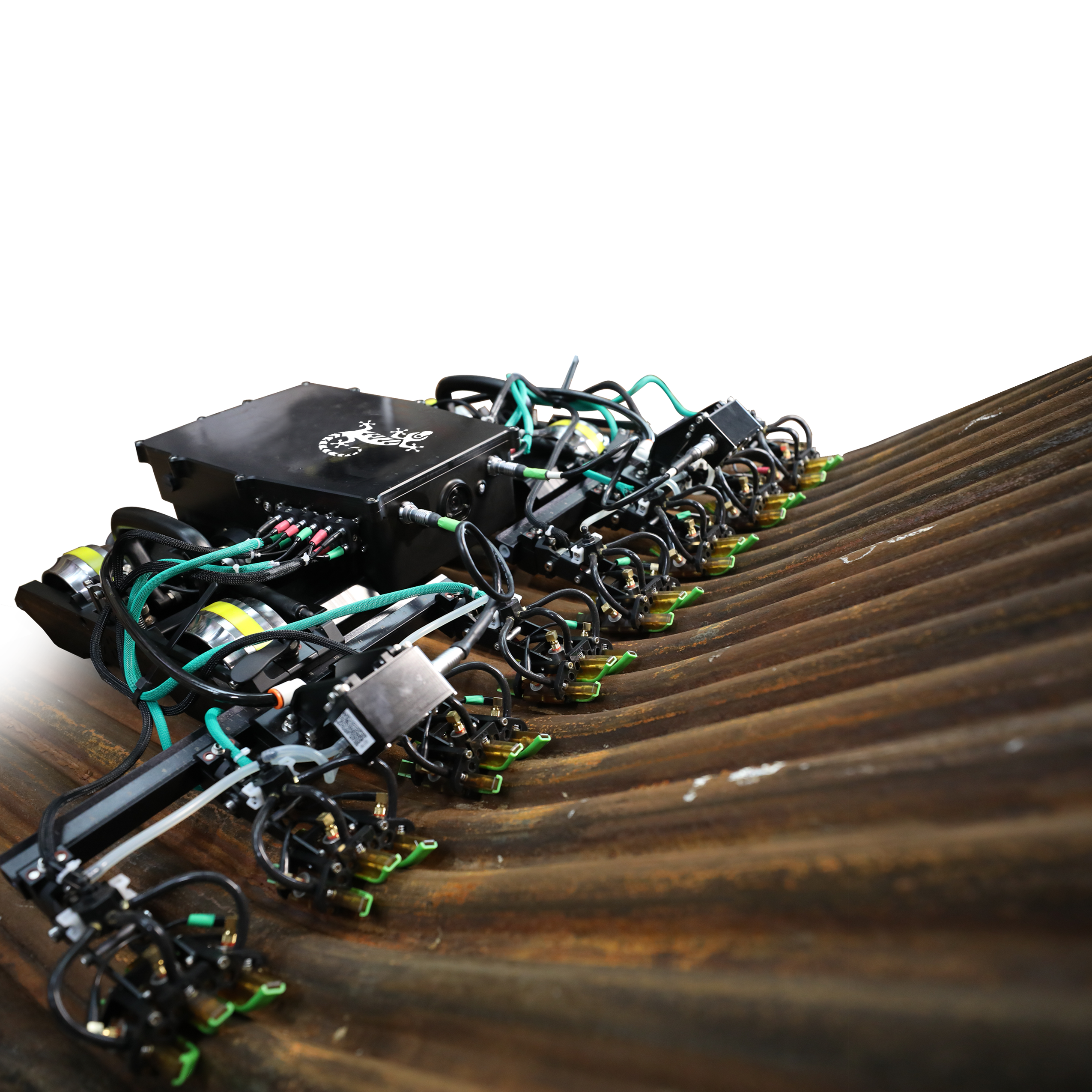

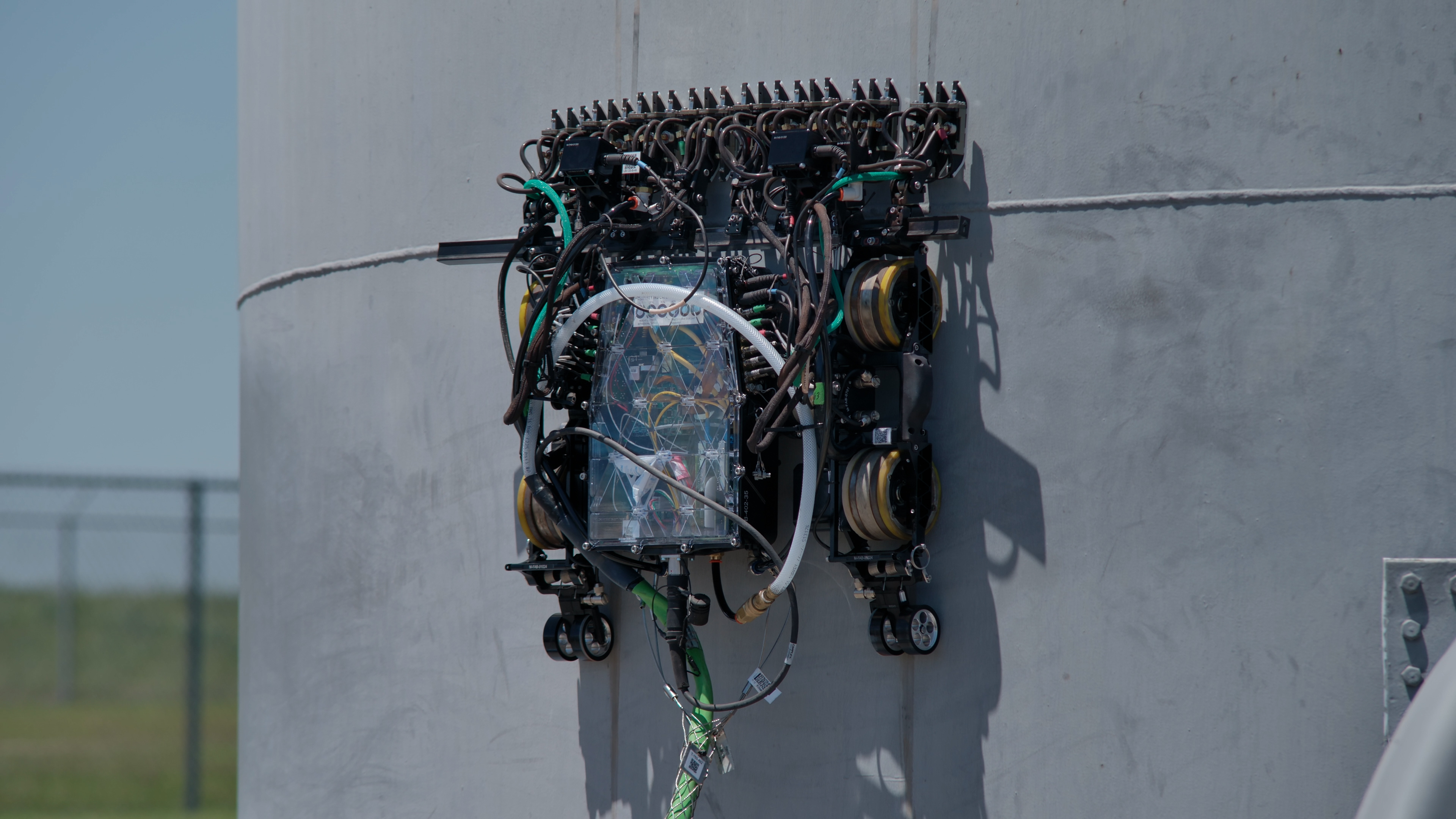

Highly versatile, efficient, safe, and modular, our robots can be deployed on fixed equipment of various geometries, including boilers, tanks, pressure vessels, piping, and more.

Ensure the performance of energy generating assets through robotic ultrasonic, visual, and magnetic induction inspection methods.

- Boilers - Regular water wall inspection and targeted repairs reduce forced outages and increase energy production

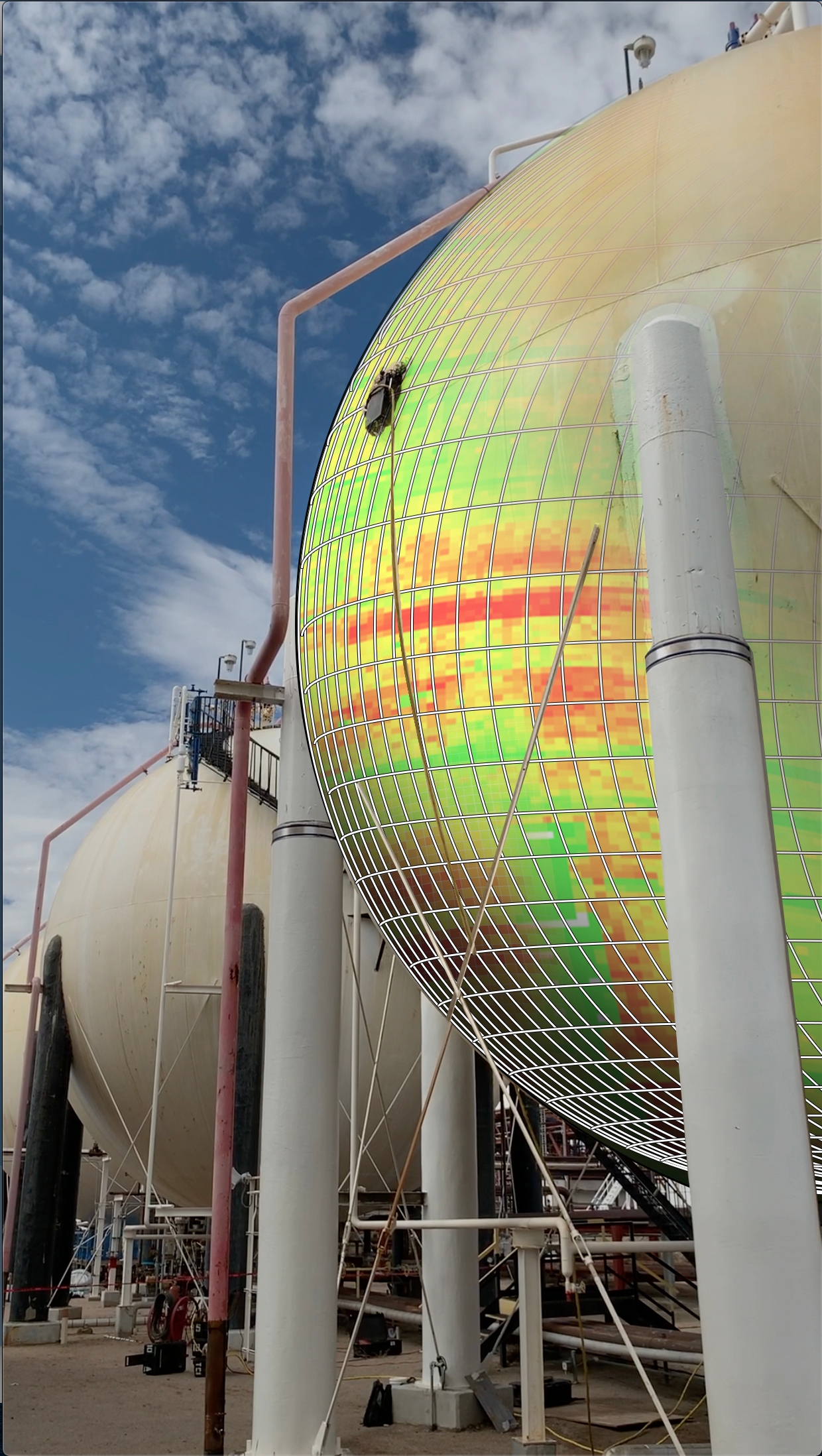

- Tanks - Covering up to 15m2, internal or external shell and roof inspections prevent failures and loss of containment

- Scrubbers - Maintain the structural integrity of essential greenhouse gas reduction equipment

- Silos - Prevent degradation and reduce onsite EHS risks with full-coverage robotic inspection

Improve mechanical integrity planning through full-coverage, data dense automated ultrasonic and phased array inspections

- Tanks - Covering up to 15m2, internal or external shell and roof inspections prevent failures and loss of containment

- Pressure vessels - Avoid opportunity cost and reduce the risk of de-rating and failure with external, in-service robotic inspections of the shell, head, and weld seams

- Piping - Improve piping integrity and reduce production losses with full coverage inspections that provide UT data along the entire length of the pipe

Maintain stable paper product manufacturing through robotic ultrasonic, visual, and magnetic induction inspection methods.

- Power Boiler: Ensure consistent and reliable energy production to fuel mill operations through full coverage robotic inspection and corrosion mapping

- Recovery boilers - Robotic solutions pinpoint pitting, under deposit corrosion (UDC), and other damage mechanisms in furnace tubes before leaks or failures occur

- Tanks - From the roof and shell, to everything in between, robots efficiently inspect in-service tanks without access requirements to inform tank integrity programs

- Digester: Efficiently inspect high pressure and high temperature digesters without confined space entry to ensure safe and reliable operation

Robotic technology

Robotic inspection methods

Advanced ultrasonic inspection robots collect data to understand the current condition of critical infrastructure, promoting safety, reducing downtime and opportunity cost, increasing efficiency, and providing high-quality point-level data. Rapid Ultrasonic Gridding (RUG) is a robot-enabled ultrasonic and visual inspection technique that produce 2D & 3D thickness grid maps to identify areas where corrosion, erosion, and other damage mechanisms have caused wall-thinning. RUG is highly versatile and can be applied to a wide range of ferromagnetic fixed equipment, including boilers, tanks, pressure vessels, piping, and more.