Concentrated solar power plants

With a daily start-up and shut-down high demands are placed on CSP-plants. Our power generation equipment and instrumentations and controls enable plant operators to make highest efficient use of every single sun beam.An inexhaustible source

Concentrated solar thermal power is worldwide becoming a more and more important source for power generation. The reasons for this are obvious: The sun is an inexhaustible source for power production. And it is not only a free fuel source but also a complete emissions-free source. Steam turbine generator sets convert solar energy into electricity. Instrumentation and controlls help to make optimal use of every single sun beam. We equipped more than 70 CSP plants all over the world and we are the market leader in that field.

The right equipment for every CSP technology

Since the solar boom of the eighties in USA, solar thermal energy has been a proven technology. The most common type of plant is the parabolic trough collector, but alternative technologies are rapidly coming to the fore, such as Linear Fresnel collector plants with flat mirrors and central tower plants with slightly curved mirrors or heliostats.

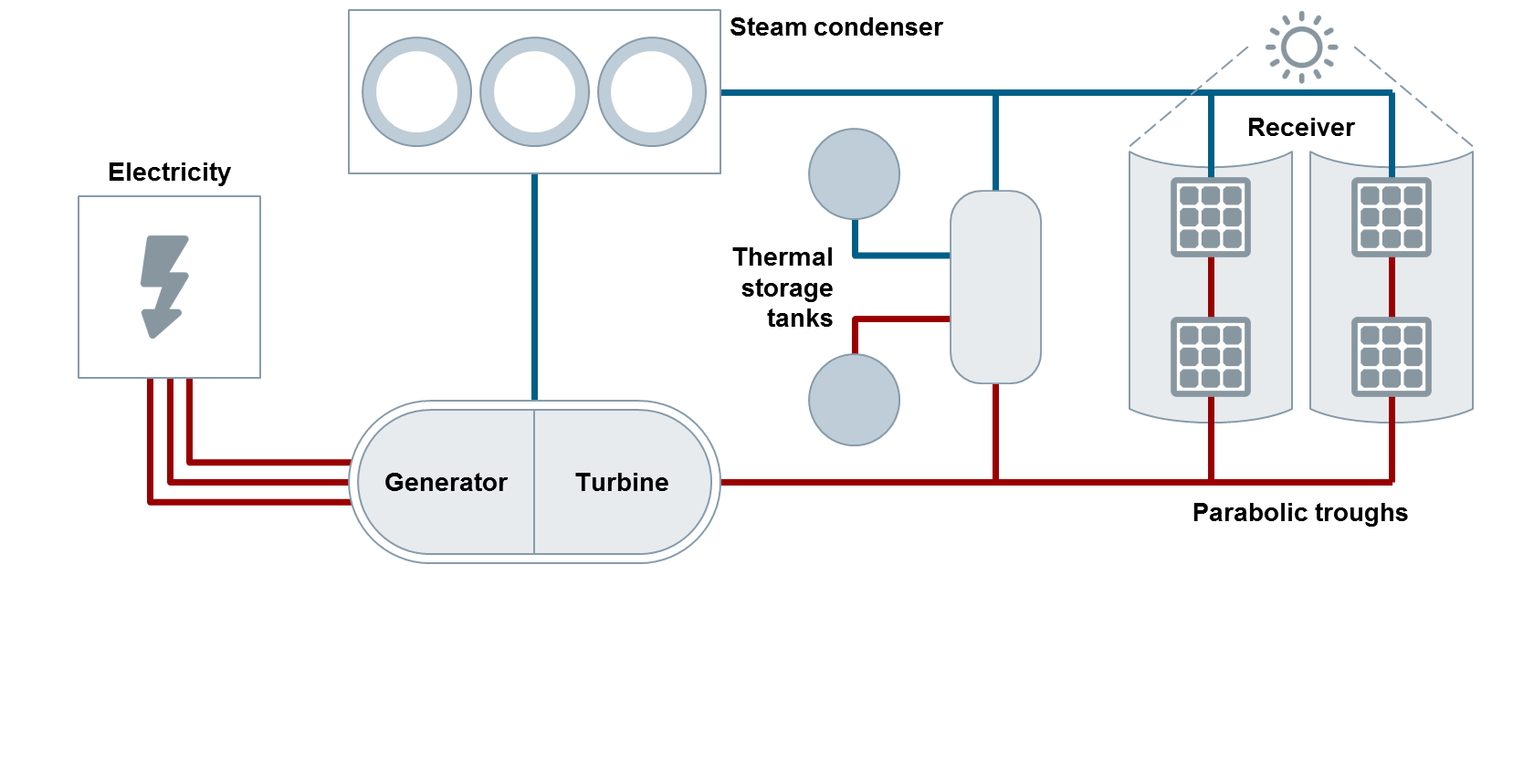

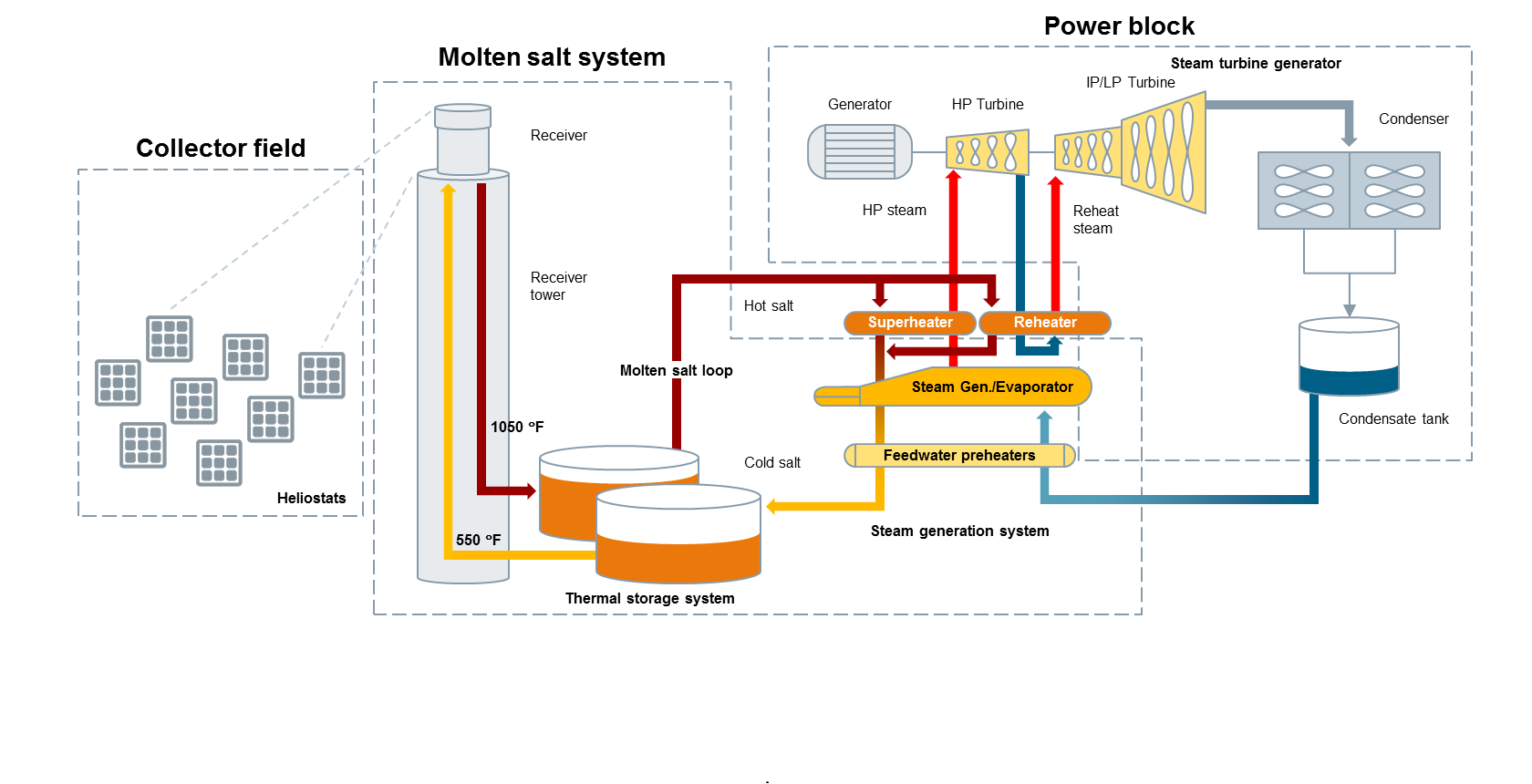

The basic principle is the same for all three plant technologies: Mirrors concentrate the incident solar radiation onto a receiver where it is converted into heat that is used to produce steam to drive a steam turbine. Heat storage systems like molten salt tanks provide for power supply even during unfavorable weather conditions or at night. They significantly increase the number of full-load operation hours with optimal steam turbine efficiency.

Turbines for all main CSP technologies

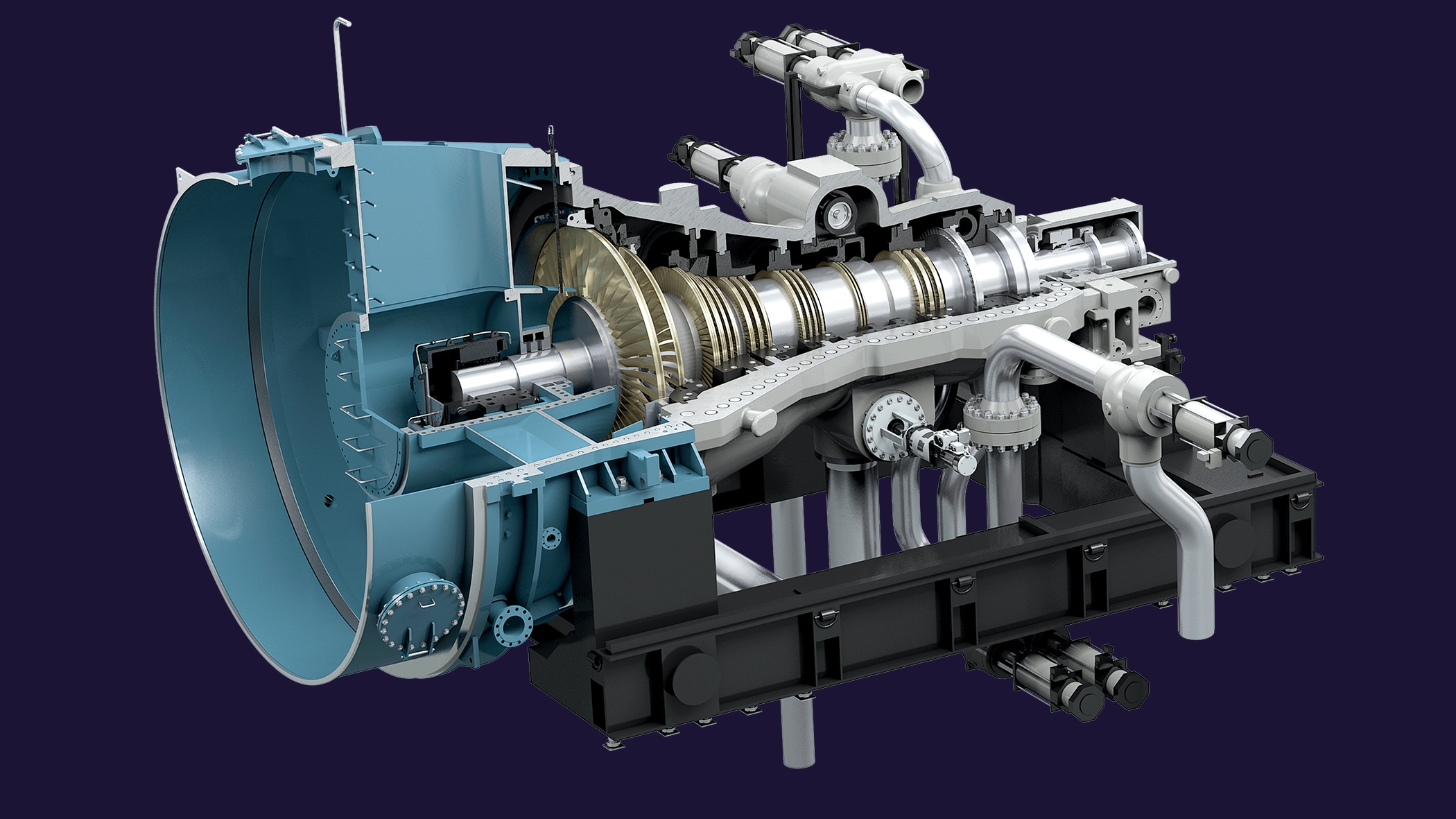

With our broad steam turbine portfolio,we offer a range of turbines for different types of solar plants and all power outputs. The turbine technology fits all three common concentrated solar power concepts. We were the first steam turbine supplier to re-enter the CSP market in the 21st century, pioneering commercial solutions in the US and Spain. Today, we are the world market leader in steam turbines for CSP plants, and have more than 20 years of experience with steam turbines for daily cycling.

Parabolic trough technology

Parabolic systems use trough-shaped mirrors to focus sunlight onto an absorber tube (receiver) placed in the trough’s focal line. The troughs are designed to track the sun along one axis, predominantly north-south. The receivers contain a heat transfer fluid (e.g. synthetic thermal oil, molten salt) which is heated by the focused sunlight. It is circulated in these tubes and pumped through heat exchangers to produce steam.

The parabolic trough technology is currently the best proven and most used technology, even though the live steam parameters are lower than in solar power tower plants.

Solar power tower

A circular array of flat heliostats (suntracking mirrors) concentrates sunlight on to a central receiver at the top of a tower. A heat transfer medium (water/steam, molten salt or air) in the receiver absorbs the thermal energy and transfers it into the steam cycle to generate superheated steam for the turbine.

The advantage over the parabolic trough or Fresnel collector concept is that the sunlight on the central receiver is focused to a smaller area, and the heat transfer medium does not have to be piped around the large solar field. This means that higher working fluid temperatures in the receiver (up to 1000°C) and better steam parameters are feasible, even supercritical steam is expected.

Typical regimes of operation

The number of concentrated solar power plants has increased tremendously in the past ten years. Today we see many different regimes of operations, each of which poses a different challenge to power generation equipment. The design of each steam turbine is adapted to these challenges.

Examples for the regimes of operation for a solarthermal power plant, with a power output of 50 MW:

Perfect steam turbines for all requirements

As market leader in industrial steam turbines, we command a comprehensive product portfolio for solar thermal plants, covering the full range from 1.5 MW to more than 250 MW.

Dispatchability with instrumentation and controls

We provide optimal instrumentation and controls (I&C) design for CSP & Hybrid-PV plants for achieving the full dispatchability of solar energy power plants. With start-up and shut-down 365 days a year, high demands are placed on your plant even on the sunniest of days. Thanks to our I&C’s integration expertise in steam turbine controls, balance-of-plant, and solar fields the plant’s performance is optimized and long-term reliability is maintained.

With the Digital Enterprise solution portfolio, we offer all the controller and drive components necessary for turning good ideas into even better system solutions under one roof – for the entire range of solar production machines and solar trackers.

CSP steam turbine highlights

References

Our industrial steam turbines for solar solutions are ordered by customers all over the world and provide energy at CSP plants in the US, Spain, Germany, India and Northern Africa. Below you can find a view selected references.

Industrial steam turbines – tailor-made and flexible

As a market leader for industrial steam turbines, we offer a comprehensive range of reliable and versatile steam turbines for the power output range from 2 to 250 MW. Our industrial steam turbines are designed for easy constructability, fast start-up and economical operation.